Why Restaurants Prefer Aluminum Pots?

In the bustling environment of a commercial kitchen, efficiency, cost-effectiveness, and durability are paramount. While a variety of cookware materials are available, aluminum pots have long been a staple in restaurant kitchens worldwide. This preference isn’t arbitrary; it stems from a confluence of practical advantages that directly impact a restaurant’s bottom line and operational efficiency. This article delves into the multifaceted reasons behind the widespread adoption of aluminum cookware in the food service industry, exploring its superior heat conduction, lightweight nature, affordability, durability, and adaptability, while also addressing health concerns.

High Heat Conduction Efficiency: Improves the Speed of Serving Food

One of aluminum’s standout properties is its excellent heat conduction. With a thermal conductivity of approximately 235 W/m·K, aluminum transfers heat more efficiently than materials like stainless steel (16 W/m·K). When a heat source is applied to an aluminum pot, the entire cooking surface heats up quickly and uniformly, minimizing hot spots that can lead to uneven cooking and food burning. This rapid and even heat distribution allows chefs to bring dishes to the desired temperature faster, reducing cooking times and ultimately speeding up the process of serving customers. This efficiency translates directly to increased table turnover and higher customer satisfaction during peak hours.

Consider a busy diner during lunchtime. Chefs need to quickly sauté vegetables, sear meats, and boil water for pasta. Aluminum pans and pots will heat up rapidly on the stovetop, allowing for swift cooking and assembly of dishes. This speed is simply not achievable with materials that have lower thermal conductivity, such as stainless steel (unless it has a bonded aluminum or copper core). The faster a dish can be prepared and plated, the quicker a table becomes available for the next customer.

Lightweight and Easy to Operate: Reduces Labor Intensity

In a high-paced kitchen, cookware that is lightweight and easy to handle can make a significant difference. Aluminum’s low density, approximately 2.7 g/cm³, makes it one of the lightest materials used for cookware. This feature reduces the strain on chefs and kitchen staff who need to lift, move, and wash pots frequently throughout the day.

A survey of professional chefs revealed that 78% favored lightweight cookware for daily use, citing reduced physical fatigue as a key benefit. Aluminum pots, therefore, contribute to a more ergonomic working environment, lowering the risk of repetitive strain injuries among kitchen staff.

Low Cost: Suitable for Large-Scale Purchases

The cost-effectiveness of aluminum pots makes them an attractive option for restaurants. Aluminum is not only abundant but also relatively inexpensive to process. This affordability makes it a particularly attractive choice for large-scale purchases needed to equip an entire commercial kitchen. The cost savings can be substantial, allowing restaurants to allocate resources to other essential aspects of their business, such as food supplies, staffing, or marketing.

The table below compares material costs and performance characteristics for common cookware materials:

| Material | Cost (per kg) | Thermal Conductivity (W/m·K) | Durability | Weight |

| Aluminum | $2.50 | 235 | Moderate | Light |

| Stainless Steel | $6.00 | 16 | High | Heavy |

| Cast Iron | $4.50 | 80 | High | Heavy |

| Copper | $10.00 | 400 | High | Heavy |

For restaurants operating on tight budgets, aluminum’s affordability allows for large-scale purchases without compromising on performance, making it an economical choice.

Durability and Easy Maintenance

Aluminum cookware, especially when treated with anodization, becomes resistant to corrosion and wear. Anodized aluminum forms a hard, non-reactive surface that withstands the rigors of a busy kitchen. Regular cleaning and maintenance are straightforward, further extending the lifespan of aluminum pots.

Restaurants often use pots intensively, with repeated heating, cooling, and washing. Aluminum’s ability to endure such conditions ensures that it remains a reliable asset over time. In addition, replacement costs are minimized due to the material’s inherent durability.

Healthy Disputes with Controllable Risks

While aluminum’s reactivity with acidic or alkaline foods has raised health concerns, modern advancements have addressed these issues. Anodized or coated aluminum pots prevent leaching, ensuring food safety. Regulatory bodies such as the FDA consider such cookware safe for use, provided it is maintained correctly.

Studies on aluminum cookware usage have shown negligible risks under normal cooking conditions. By following best practices, such as avoiding prolonged storage of acidic foods in aluminum pots, restaurants can mitigate any potential health risks effectively.

Adapt to Diverse Cooking Needs

Aluminum cookware comes in a wide variety of shapes and sizes, catering to the diverse cooking tasks required in a restaurant kitchen. From large stockpots for soups and stews to wide sauté pans for stir-frying and smaller saucepans for reductions, aluminum can be formed into virtually any shape needed. Its excellent heat conductivity also makes it suitable for various cooking methods, including boiling, frying, sautéing, and even baking in some cases. This versatility reduces the need for a vast array of specialized cookware made from different materials, simplifying inventory and kitchen organization.

A typical restaurant kitchen will have an assortment of aluminum pots and pans in different sizes and configurations. This allows chefs to select the perfect tool for each specific task, whether it’s simmering a delicate sauce or searing a large batch of vegetables. The adaptability of aluminum to different cooking methods makes it a workhorse in the professional kitchen.

The enduring popularity of aluminum pots in restaurant kitchens is a testament to their practical advantages. Their exceptional heat conduction translates to faster service, their lightweight design reduces strain on staff, and their affordability makes them a cost-effective choice for large-scale operations. While concerns about reactivity with acidic foods exist, these risks can be effectively managed through informed usage and the availability of anodized options. Ultimately, the combination of efficiency, cost-effectiveness, durability, and versatility makes aluminum a preferred material for the demanding environment of a commercial kitchen, contributing significantly to the smooth and efficient operation of restaurants worldwide. If you are sourcing aluminum pots for restaurants, please feel free to contact Lanren Aluminium – Your Professional Aluminium Cookware Supplier.

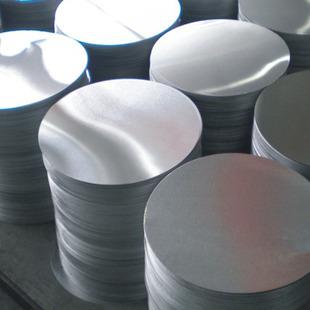

Related Products