What Are the Applications of Aluminum in Cookware?

In modern kitchens, cookware is made of a variety of materials, and aluminum, as a common metal material, occupies an important position in the field of cookware manufacturing. From simple home kitchens to professional catering places, aluminum cookware can be found everywhere. Its wide application is not only due to its abundant reserves and relatively low cost, but also due to its unique material properties and various processing methods. Now, let’s explore the application of aluminum in cookware.

What Makes Aluminum Ideal for Cookware?

Aluminum is an ideal material for cookware, mainly due to its unique material and process properties, which give it significant advantages in cookware manufacturing. The following is a detailed analysis:

Material properties

Physical properties

Aluminum’s physical properties play a key role in making it an ideal material for cookware. These characteristics affect many aspects of the cooker, including user experience and efficiency.

- Lightweight: Aluminum has a relatively low density compared to stainless steel, cast iron, and ceramic, making aluminum cookware products lighter in weight. For example, in daily use, aluminum frying pans are lighter to hold, which reduces the operating burden for users with less strength or chefs who need to use the cooker for a long time. When camping outdoors, aluminum kettles, lunch boxes and other cooking utensils are light and easy to carry and use.

- Good thermal conductivity: Aluminum is an excellent conductor of heat, which can quickly conduct heat to the entire surface of the cookware. For example, when cooking delicious food in a frying pan, the heat can be evenly distributed on the bottom of the pan, making the food heated more evenly and reducing the chance of food burning due to local overheating. This good thermal conductivity helps improve cooking efficiency and food quality.

- Low Melting Point: Aluminum has a relatively low melting point, which makes it easier to handle during processing and forming. When manufacturing cookware with complex shapes, a variety of processing techniques can be used, such as die casting, to meet diverse design requirements.

- Good gloss: Aluminum has a certain metallic luster, which makes aluminum cookware attractive in appearance. New aluminum cookware has a shiny finish and lends a clean, modern feel to any kitchen setting.

Chemical properties

The chemical properties of aluminum also have an important impact on its use in cookware, determining aspects such as its safety and durability.

- Corrosion resistance: A dense aluminum oxide film will naturally form on the surface of aluminum, which can protect the aluminum substrate from further corrosion.

- Chemical stability: Within normal cooking temperature and pH range, aluminum has relatively stable chemical properties and will not release harmful substances, thus ensuring the health of users. However, it should be noted that aluminum will react chemically in strong acid or alkaline environments, so avoid cooking foods with such extreme pH levels when using aluminum cookware.

Process Characteristics

The processing characteristics of aluminum provide strong support for its wide application in cookware manufacturing, enabling it to be processed into various types of cookware in a variety of ways.

- Good formability: Aluminum can be formed through a variety of processes such as stamping, die casting, and stretching. For example, stamping can create the shape of a frying pan, die-casting can produce cookware with complex patterns or structures, and stretching is suitable for manufacturing some thin-walled aluminum containers, such as aluminum kettles. Good formability allows aluminum cookware to have a variety of shapes and structures to meet different cooking needs.

- Various surface treatments: Aluminum cookware can be anodized, painted, electroplated and other surface treatments. Anodizing can increase the hardness and wear resistance of aluminum while also changing its color; painting can add color and decorativeness to cookware; electroplating can coat aluminum with a layer of other metals, such as stainless steel, to increase its resistance. corrosion or improve its appearance. A variety of surface treatments provide a variety of options for improving the performance and appearance of aluminum cookware.

These properties make aluminum a versatile and efficient choice for cookware, ideal for a range of cooking methods and styles.

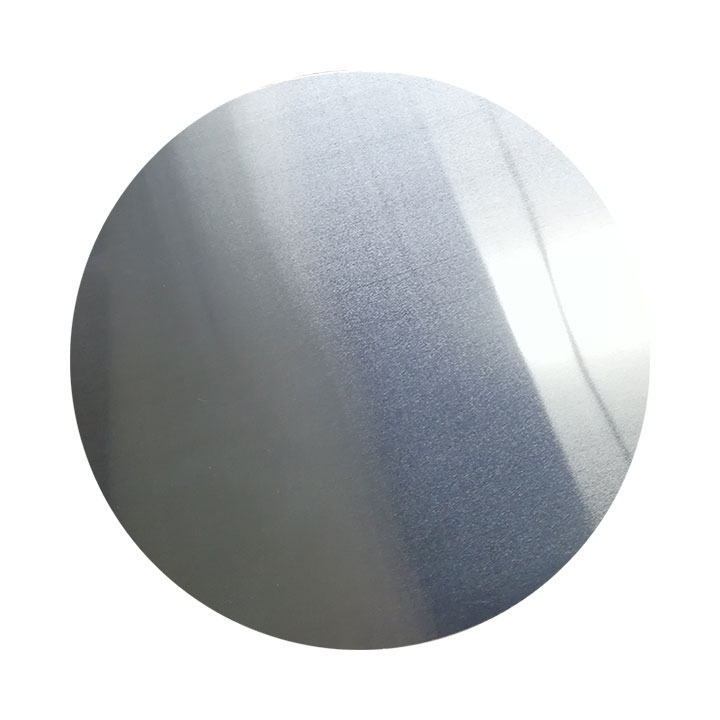

Types of Aluminum in Cookware

In the manufacture of cookware, different types of aluminum materials are used, which have different performance characteristics to meet the needs of various cookware.

Pure aluminum: Pure aluminum has good thermal conductivity and ductility, but low hardness. In some cookware that requires extremely high thermal conductivity and is used in a relatively mild environment, such as some small aluminum soup spoons, pure aluminum is used.

Aluminum alloy: Aluminum alloy is a material made by mixing aluminum with other elements (such as magnesium, manganese, silicon, etc.). The alloyed aluminum improves properties such as hardness, strength and corrosion resistance. Most aluminum cookware, such as aluminum frying pans, aluminum pressure cookers, etc., are made of aluminum alloys.

Common cookware grades of aluminum alloys are:

| Aluminum Alloy Grade | Characteristics | Examples of Cookware Manufactured |

| 1060 | High plasticity, corrosion resistance, electrical and thermal conductivity, good elongation and tensile strength, and excellent processability for forming. | Simple aluminum – made soup spoons and small containers, suitable for containing and briefly heating food. |

| 1100 | Excellent ductility, formability, weldability and corrosion resistance. After anodizing, the corrosion resistance is enhanced and the surface is beautiful. | The inner liner of aluminum – made frying pans. It is easy to be formed and the surface is suitable for cooking contact. |

| 3003 | Good corrosion resistance, stable performance in various environments; easy to be processed and formed, with moderate plasticity and strength; non – toxic and harmless; wear – resistant and corrosion – resistant, with a long service life; beautiful appearance after surface treatment; low density and lightweight. | Aluminum – made pressure cookers and soup pots, which can meet the requirements of strength and cooking needs. |

Applications of Aluminum Cookware in Different Cooking Styles

Aluminum’s versatility is especially evident in its applications across various cooking styles, including frying, baking, steaming, and more.

- Frying Pans and Skillets: Aluminum is widely used for frying pans due to its excellent heat conduction. It allows for even cooking, making it perfect for dishes that require precise temperature control, such as eggs, pancakes, or seared meats.

- Sauce Pans and Stockpots: Aluminum’s lightweight and durability make it ideal for large stockpots and saucepans, which are used in simmering, boiling, and slow cooking.

- Baking Pans: Aluminum is a go-to material for baking trays, cake pans, and muffin tins because of its ability to heat up quickly and evenly, crucial for achieving the perfect rise and texture in baked goods.

Aluminum’s ability to adapt to different cooking techniques—whether frying, baking, or simmering—gives it broad appeal for both professional chefs and home cooks.

Common Myths About Aluminum Cookware

Despite its popularity, aluminum cookware has been the subject of numerous myths, often concerning safety and health risks.

Myth 1: Aluminum Leaches into Food and Poses Health Risks: This concern stems from the idea that aluminum exposure is linked to health issues like Alzheimer’s disease. However, modern aluminum cookware, particularly anodized or coated varieties, is considered safe for cooking.

Myth 2: Aluminum Cookware is Easily Damaged: While uncoated aluminum is softer and can scratch easily, anodized aluminum is much more durable and resistant to wear and tear.

Myth 3: Aluminum Reacts with Acidic Foods: While uncoated aluminum can react with acidic foods, anodized aluminum prevents this reaction, ensuring safety and maintaining the integrity of your meals.

While there are several myths surrounding aluminum cookware, it is important to rely on scientific findings and consumer safety standards to make informed decisions about its use. Modern aluminum cookware, especially anodized and non-stick options, are safe and durable.

From basic frying pans to specialty cookware like pressure cookers and grill pans, aluminum’s versatility makes it suitable for a wide range of cooking styles. Although there are several myths about aluminum’s safety, most modern aluminum cookware is safe and durable when used appropriately. With its recyclability and efficient cooking performance, aluminum continues to be a staple in both home kitchens and professional settings. For any aluminum cookware needs, please feel free to contact Lanren to be your aluminum cookware supplier.

Related Products