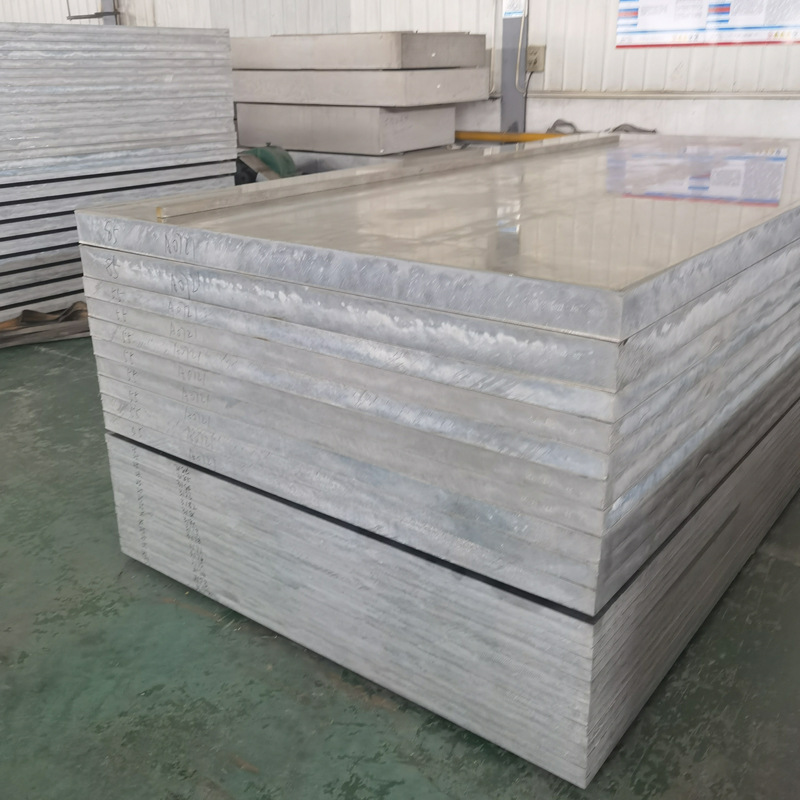

Thick Aluminum Sheet

Our high-strength thick aluminum plate is a metal material designed for high-end applications and is known for its excellent physical properties and a wide range of applications. The product is made of high-quality aluminum sheets and manufactured through a precise production process to ensure the uniformity and stability of the sheet.

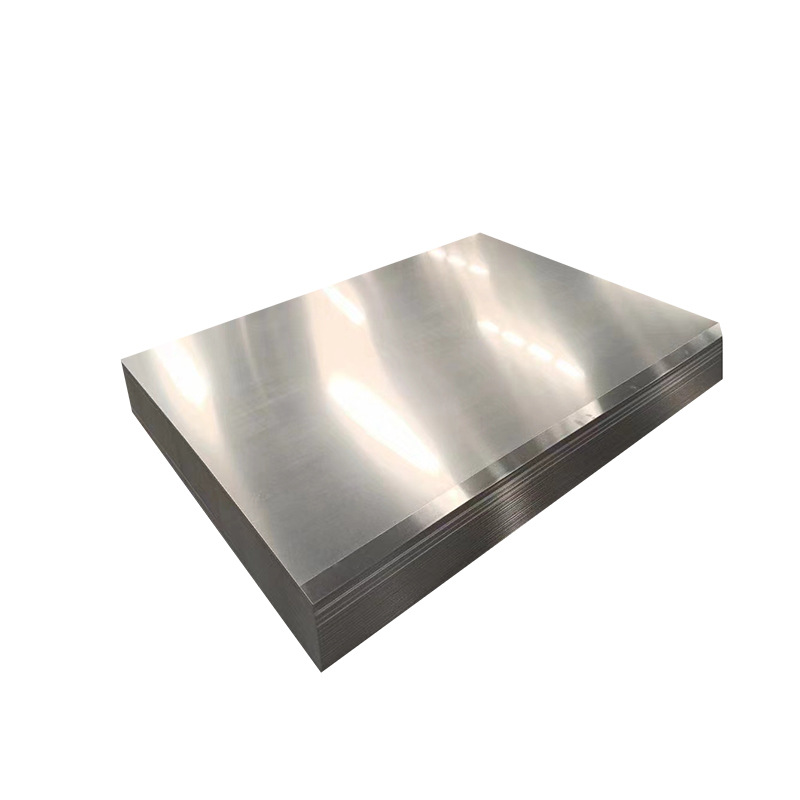

Specifications

| Parameter Category | Specific Specification |

| Thickness | 0.5mm, 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, etc. |

| Width | Up to 2800mm, customizable based on customer requirements |

| Length | Up to 6000mm, customizable based on customer requirements |

| Material | 1050, 1060, 1100, 3003, 5052, 5083, 6061, 6082, 8011, etc. |

| State | F, H112, H12, H14, H18, H20, H22, H24, H26, H32, H16, H34, T6, T4, O, etc., depending on heat treatment and processing method |

| Surface Treatment | Powder coating, anodizing, polishing, brushing, etc., to meet environmental resistance and aesthetic needs |

Advantages of Thick Aluminum Sheet

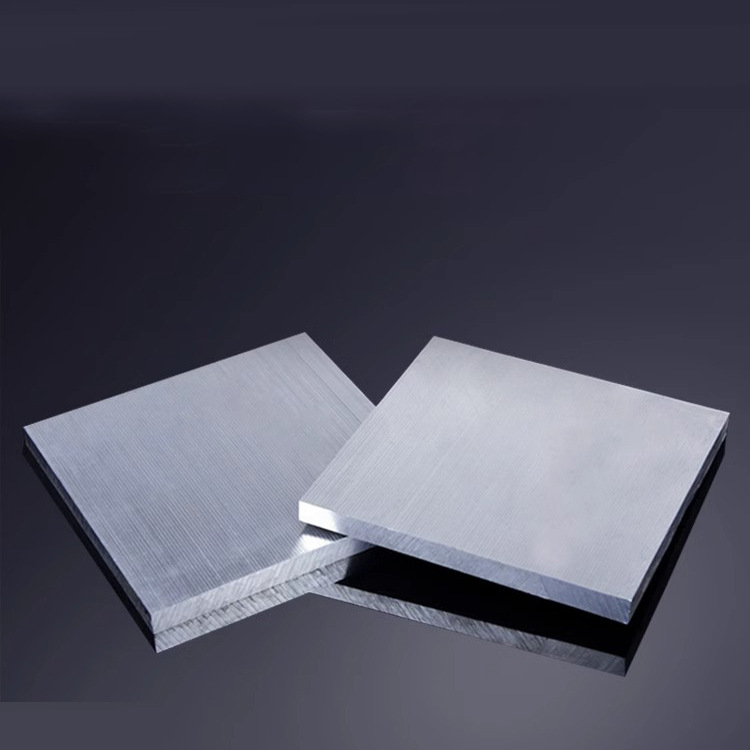

Thick aluminum plates usually refer to aluminum materials that are thicker than conventional aluminum sheets. They have significant advantages in mechanical properties compared to ordinary aluminum plates. These advantages are mainly reflected in the following aspects:

- Greater strength: Thick aluminum plates offer greater load-bearing capacity and resistance to bending due to their thicker material thickness. Certain thick aluminum plates, such as the 7075 series, can achieve extremely high strength after proper heat treatment, much better than mild steel.

- Improved fatigue strength: Thick aluminum plates exhibit better fatigue life under repeated loading, which is particularly important for applications in areas such as aerospace and transportation.

- Better Wear Resistance: Thick aluminum sheets generally have a higher hardness, which means they resist wear and scratches, extending the material’s lifespan.

- Higher impact absorption: Thick aluminum plates are able to absorb more energy when struck, which helps protect the structure from damage from sudden impacts.

- Improved thermal stability: Some thick aluminum plates can maintain good mechanical properties at high temperatures, which is very beneficial for high-temperature applications.

- Good welding performance: Although some high-strength thick aluminum plates have poor welding performance, welding can be achieved through special processes or other connection methods can be used to ensure the integrity of the structure.

These advantages make thick aluminum plates the material of choice in applications requiring high strength, wear resistance and good structural integrity. When selecting a thick aluminum plate, the requirements of the specific application should be considered to ensure the most appropriate material and performance grade are selected.

Applications

1. Construction field

Thick aluminum plates are widely used in the construction field, especially in building exterior wall decoration, roofing materials, and thermal insulation materials. For example, aluminum alloy thick plates are excellent roofing materials due to their lightweight, corrosion resistance, wind pressure resistance and other characteristics. They can not only effectively reduce the load of buildings, but also improve the wind resistance of building roofs and ensure building safety. In addition, as thermal insulation materials, aluminum alloy thick plates can be used in the exterior walls and roofs of buildings due to their low thermal conductivity, effectively improving the energy efficiency of buildings.

2. Transportation field

In the field of transportation, thick aluminum plates are widely used in the manufacture of aircraft, automobiles, and ships. In aircraft manufacturing, the high strength, excellent corrosion resistance, and good machinability of thick aluminum plates make them ideal materials for manufacturing aircraft shells, wings, and other parts. In automobile manufacturing, the use of aluminum alloy plates can reduce the weight of automobiles, improve fuel efficiency, and also improve the safety performance of automobiles. In shipbuilding, thick aluminum plates are also widely used due to their lightweight and corrosion resistance.

3. Other fields

In addition to the above two fields, thick aluminum plates also have important applications in industrial manufacturing and electrical and electronic fields. In industrial manufacturing, it can be used to manufacture pressure vessels, petrochemical equipment, etc. It has good corrosion resistance and high-temperature resistance and can meet the requirements of various complex working conditions. In the field of electrical and electronics, aluminum alloy thick plates have excellent electrical conductivity and are widely used in radiators and circuit boards of electronic equipment.