The Importance of Customization in Aluminum Discs for Specific Industry Uses

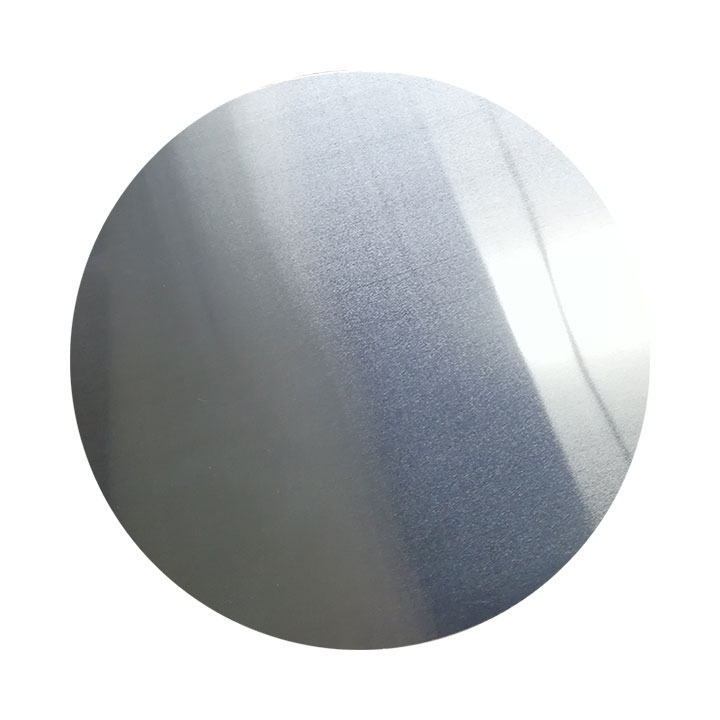

Aluminum discs, also called Aluminum Circles, are versatile components used in a wide range of industries, including automotive, aerospace, cookware, and electronics. They are lightweight, corrosion-resistant, and have good thermal conductivity, making them ideal for a variety of applications. However, the use of aluminum discs is often limited by their ability to meet specific needs, so the customizability of aluminum discs becomes very important.

Reasons to Opt for Aluminum Discs

Aluminum discs have become a staple in numerous industries due to their exceptional properties and cost-effectiveness.

- One of their standout features is their lightweight nature, which makes them ideal for applications where reducing weight is critical, such as in the automotive and aerospace sectors. Despite being lightweight, aluminum discs offer impressive durability, resist wear and maintain structural integrity under demanding conditions.

- Another key advantage is their natural corrosion resistance. The oxide layer that forms on aluminum surfaces protects the material from environmental factors, ensuring longevity in diverse settings, from industrial equipment to cookware.

- Aluminum discs also excel in thermal and electrical conductivity, making them essential for applications requiring efficient heat transfer or electrical performance.

- Lastly, aluminum is widely available and recyclable, making it a cost-effective and sustainable choice for large-scale use.

These qualities make aluminum discs an indispensable material for manufacturers seeking efficiency and performance.

Significance of Tailoring Aluminum Discs

Customization is crucial for maximizing the potential of aluminum discs, as it enables them to address the specific challenges and requirements of various applications. Standard, ready-made discs often fail to meet the high precision, performance, or durability standards needed for demanding tasks. By tailoring aluminum discs, they can be perfectly suited to the particular needs of an industry or process, offering many advantages:

- Precision Fit: Customization ensures the discs integrate seamlessly with machinery or products, reducing downtime and improving overall operational efficiency.

- Enhanced Longevity: Treatments like anodizing or protective coatings make aluminum discs more resistant to wear, corrosion, and environmental stresses, increasing their lifespan.

- Enhanced Performance: Customizing the dimensions, shapes, or finishes of aluminum discs ensures they operate at their best, enhancing key processes like heat transfer, electrical conductivity, or maintaining structural strength.

- Economic Benefits: Although custom discs may come with a higher initial cost, their superior performance and longevity typically result in long-term savings by minimizing maintenance, replacements, and material waste.

In a word, tailored aluminum discs provide industries with the flexibility to innovate and meet demanding standards, reinforcing their value as a versatile and high-performing material solution.

Essential Customization Features for Aluminum Discs

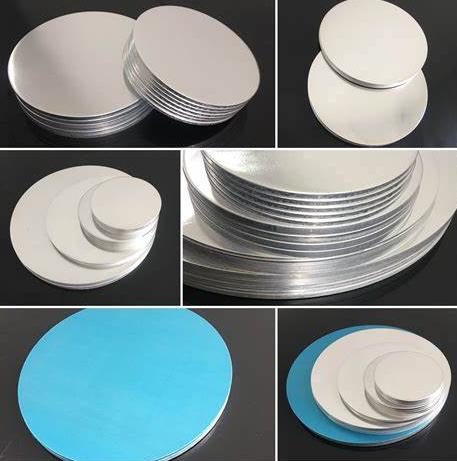

Customizing aluminum discs involves adjusting several key features to ensure optimal performance for specific applications. These features include:

| Customization Feature | Description | Benefits |

| Material Composition | Adjusting the alloy blend to meet specific strength, flexibility, or conductivity requirements. | Tailors the mechanical properties of the disc, such as increased strength, improved corrosion resistance, or enhanced thermal conductivity. |

| Dimensions and Tolerances | Modifying the size, thickness, and shape of the disc to meet precise specifications. | Ensures a perfect fit for various applications, eliminating compatibility issues and ensuring optimal performance in machinery or devices. |

| Surface Treatment | Applying coatings or finishes, such as anodizing, powder coating, or polishing, to the aluminum disc’s surface. | Improves durability, enhances corrosion resistance, and provides aesthetic finishes that suit the specific environmental or aesthetic requirements. |

| Perforations or Grooves | Introducing holes, slots, or grooves into the aluminum discs for specific functional purposes, such as improved airflow, lightness, or heat dissipation. | Custom perforations or grooves improve the functionality of the disc, such as better cooling in heat exchangers or lighter weight for automotive parts. |

| Edge Modifications | Shaping or smoothing the edges of the disc to meet safety or assembly requirements. | Enhances safety by removing sharp edges and ensures compatibility with automated or manual assembly processes. |

By adjusting these features, you can create aluminum discs that are perfectly suited to your applications, enhancing performance, longevity, and efficiency.

Industries Benefiting from Customized Aluminum Discs

Customized aluminum discs offer significant advantages across various industries.

- Automotive Industry: In automotive applications, lightweight aluminum discs are employed in parts like wheels, engine components, and body panels. Customization allows these discs to meet precise performance, strength, and weight criteria, ultimately enhancing fuel efficiency and overall vehicle performance.

- Cookware: Aluminum discs are commonly found in cookware, including frying pans and pressure cookers. Custom adjustments in thickness and the addition of non-stick coatings ensure uniform heat distribution, increased durability, and optimal performance in high-heat cooking scenarios.

- Aerospace: Aerospace components require aluminum discs that meet stringent specifications for strength and weight. Customization helps create components that can withstand extreme conditions while reducing the overall weight of aircraft.

- Electronics: Customized aluminum discs are crucial in electronic devices, often used as heat sinks to dissipate heat efficiently. Tailored properties ensure maximum thermal conductivity, enhancing device longevity.

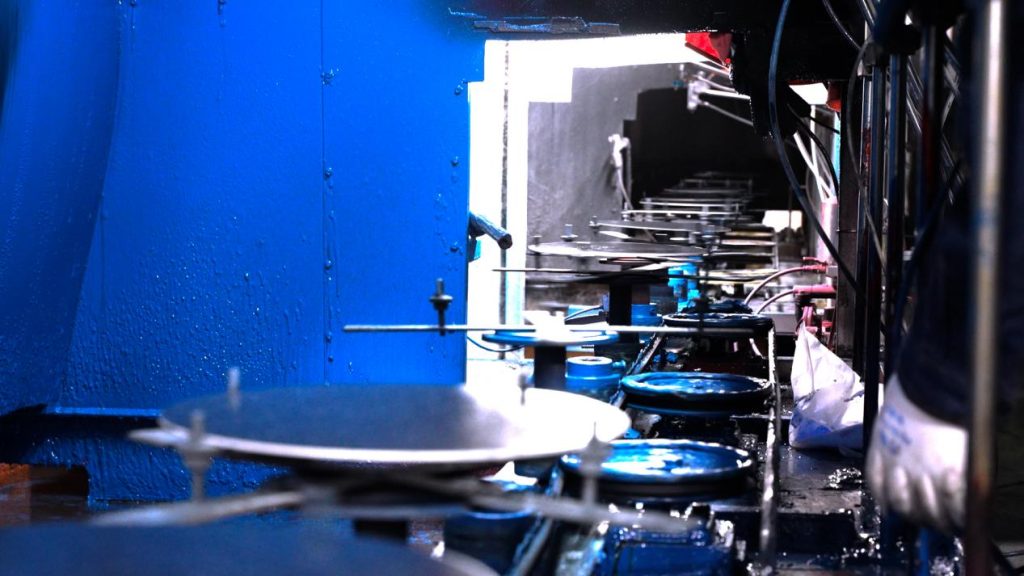

- Manufacturing: Customized sizes and specifications are crucial for aluminum discs in manufacturing processes like stamping or machining, ensuring precision and optimal performance.

Conclusion and Key Takeaways

Customization transforms aluminum discs from standard components to indispensable, high-performance tools tailored to unique industry needs. By opting for tailored solutions, industries can achieve greater efficiency, durability, and functionality in their operations.

Key takeaways include the importance of selecting the right alloy composition, dimensions, and finishes to meet specific demands. As industries continue to innovate, the role of customized aluminum discs will undoubtedly grow, cementing their position as a cornerstone of industrial versatility and efficiency. For any need of wholesale customizable aluminum discs, please contact Lanren.

Related Products