Pure Aluminum Coil

Lanren’s Pure Aluminum Coil is a premium product designed to meet the high standards of various industries worldwide. Recognized for its exceptional properties, including corrosion resistance, lightweight, and superior thermal conductivity, this aluminum coil is engineered for durability and adaptability. It serves as an essential material in industries ranging from construction and automotive to electrical and packaging, offering solutions that are both cost-effective and sustainable.

Description

- Lanren’s Pure Aluminum Coil is manufactured from the finest quality aluminum, with purity levels ranging from 99.0% to 99.9%. The coil undergoes a meticulous production process to ensure consistency in quality, including precise rolling and heat treatment to achieve the desired temper and mechanical properties. The surface of the aluminum coil is finished to perfection, providing a smooth, clean, and uniform appearance, which is crucial for applications requiring a high aesthetic standard.

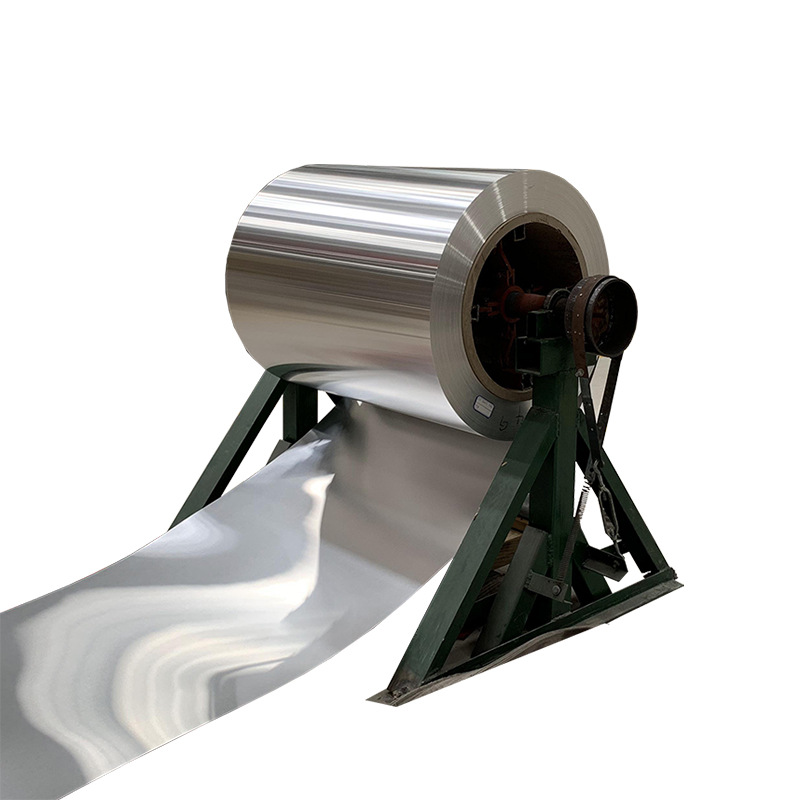

- This product is available in various thicknesses, from ultra-thin sheets to more robust gauges, making it versatile enough to be used in a wide array of applications. The width of the coil can be customized to suit specific needs, providing flexibility in its use. Additionally, the coil is available in several temper grades, such as H14, H18, H22, H24, and O, each offering different levels of strength and ductility to cater to specific operational requirements.

- Lanren’s commitment to quality means that each coil is rigorously tested for performance, ensuring it meets international standards such as ASTM, EN, and JIS. This dedication to excellence makes our pure aluminum coil an ideal choice for industries that demand reliable, long-lasting materials.

Specification

- Material Composition: 99.0% – 99.9% Pure Aluminum

- Temper Options: H14 (Half-Hard), H18 (Full-Hard), H22 (Quarter-Hard), H24 (Half-Hard), O (Annealed)

- Thickness Range: From 0.2mm to 6.0mm, accommodating various industrial requirements.

- Width Range: Available in widths ranging from 100mm to 2000mm, suitable for both narrow and wide applications.

- Coil ID (Inner Diameter): Options include 150mm, 200mm, 300mm, 400mm, and 500mm to fit various machinery and equipment setups.

- Surface Treatments:

- Mill Finish: For a smooth and reflective surface, ideal for general applications.

- Anodized: Enhances corrosion resistance and surface hardness, suitable for decorative and protective purposes.

- Coated: Available with a variety of coatings to enhance specific properties like UV resistance, color, and durability.

Features

- Exceptional Corrosion Resistance: The inherent properties of aluminum, combined with its natural oxide layer, provide a formidable defense against rust and corrosion. This makes the coil highly durable, even in harsh and corrosive environments like marine or chemical processing applications.

- Lightweight with High Strength: Aluminum’s low density means it is significantly lighter than steel, yet it does not compromise on strength. This makes it particularly valuable in industries where weight is a critical factor, such as aerospace and automotive manufacturing.

- Superior Thermal Conductivity: Aluminum is renowned for its ability to conduct heat efficiently, making our pure aluminum coil an ideal choice for heat exchangers, radiators, and other thermal management applications.

- Outstanding Electrical Conductivity: Pure aluminum is an excellent conductor of electricity, which is why it is frequently used in the electrical industry for components like cables, transformers, and conductive materials.

- Excellent Workability and Formability: The material’s malleability allows it to be easily shaped, bent, and formed into complex configurations without compromising its structural integrity. This makes it suitable for a wide range of fabrication processes.

- High Recyclability and Eco-Friendliness: Aluminum is fully recyclable, and its recycling process requires significantly less energy than producing new aluminum from raw ore. This contributes to the sustainability of your operations, aligning with eco-friendly initiatives and reducing the environmental footprint.

Applications

- HVAC Systems: The high thermal conductivity and corrosion resistance of pure aluminum make it an essential material in the production of heat exchangers, condensers, and evaporators, contributing to the efficiency and longevity of HVAC systems.

- Electrical Industry: The coil’s excellent electrical conductivity is leveraged in the manufacturing of cables, bus bars, and electrical connectors. It is also used in power transmission lines and transformer windings where efficient conductivity and lightweight materials are critical.

- Automotive Industry: In the automotive sector, the pure aluminum coil is used in body panels, heat shields, and other components that require a balance of lightweight properties and strength. It contributes to improved fuel efficiency and reduced emissions by lowering the overall vehicle weight.

- Construction and Architecture: Aluminum’s durability, corrosion resistance, and formability make it ideal for roofing, cladding, and curtain walls. It is also used in structural applications where long-lasting and aesthetically pleasing materials are required.

- Packaging Industry: The non-toxic, lightweight, and corrosion-resistant nature of aluminum makes it an excellent choice for packaging, especially in the food and beverage industry where it is used for foil wraps, containers, and cans.

- Aerospace Industry: The aerospace sector benefits from the lightweight and high-strength properties of pure aluminum in the manufacturing of aircraft skins, fuselage, wings, and other structural components that demand both performance and durability.

- Marine Industry: Aluminum’s resistance to saltwater corrosion makes it suitable for marine applications, including shipbuilding, offshore platforms, and marine fittings.