Production Process of Aluminium Circles and It Uses

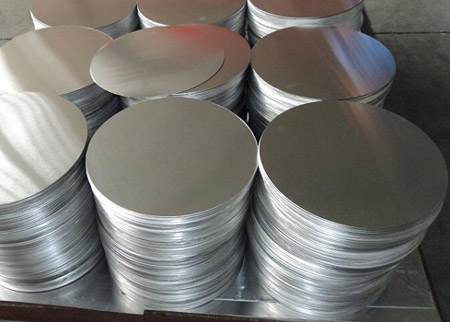

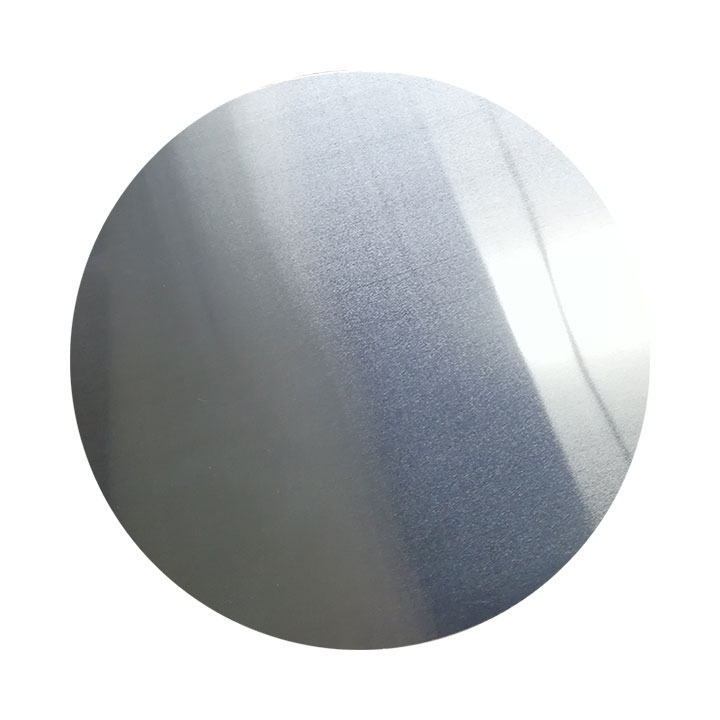

Aluminium Circles, also named Aluminum Disc, are mainly used for processing that requires good forming properties and high corrosion resistance. Aluminium circles have good forming and processing properties, corrosion resistance, handleability, fatigue strength and medium static strength.

The Process of Aluminum Circles

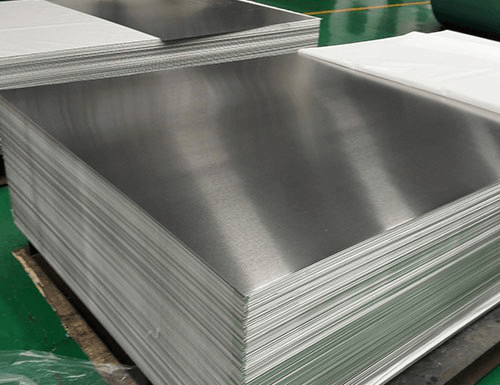

The deep processing of aluminum circles is already an indispensable technology. Aluminium circles are products obtained after deep processing of aluminum plates. They suffer relatively large demand on the market.

The surface of aluminium circles is bright and beautiful, and it is a commonly used material for kitchenware. The aluminium circle uncoiling blanking production line is an automated production line specially designed and manufactured for the production of aluminium circles for cooking utensils, aluminium circles for lamps, etc., which can meet the production needs of a large number of aluminium circle blanks of enterprises.

So what are the technical characteristics of the production of aluminium circles? Let’s learn about the aluminium circle production process:

- 1. CNC(Computer Numerical Control) fully automatic. The production line starts from the unwinding of the coil until the entire roll of material is completely blanked. There is no need for manual contact with any materials and no adjustments. This fundamentally eliminates the hidden dangers of production safety and product quality of ordinary punching.

- 2. The line can directly use the coil to produce wafers, without the need for slitting and cross-cutting of the coil, which reduces the production process, reduces the production cost, and reduces the possibility of damaging the surface of the coil.

- 3. The aluminium circle unwinding and blanking production line makes full use of the width of the coil, and is controlled by a high-precision servo motor drive system to reduce the distance between the wafer and the distance from the wafer to the edge of the material, and radically reduce the amount of waste.

- 4. Due to the modular mold design, when converting circle production specifications, the conversion time can be reduced to less than 15 minutes. The diameter of the discs that can be produced ranges from 85mm to 700mm.

- 5. Advanced uncoiling system, six-fold leveling machine, high-rigidity mechanical press, automatic palletizing system, etc., ensure the high quality of aluminium disc products.

Industries in Which Aluminium Circles May be used.

Aluminium circles are mainly used for processing that requires good forming properties and high corrosion resistance. Aluminium circles have good forming and processing properties, corrosion resistance, handleability, fatigue intensity and medium static intensity.

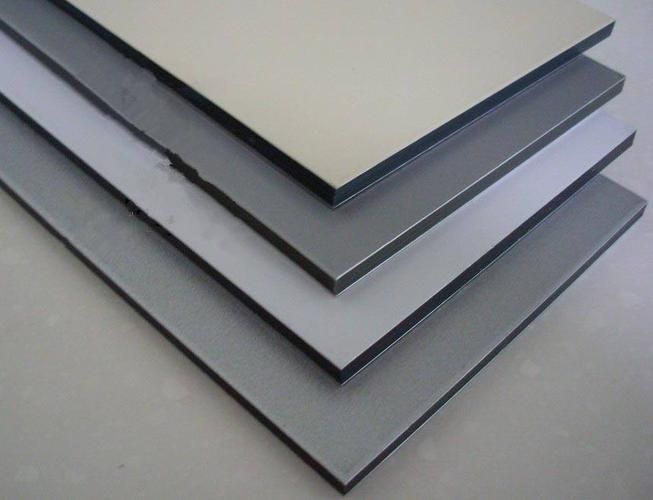

Aluminium circles are widely used in electronics, daily chemicals, medicine, culture and education, and auto parts. Aluminium circles could be used in electrical appliances, heat preservation, machinery manufacturing, automobiles, aerospace, military industry, molds, construction, printing and other industries. With the continuous development of science and technology, aluminium circles have been developed and applied in many fields such as industry.

Chongqing Lanren Aluminium Co.,Ltd – Lan ren was established in 2008,which is a professional manufacturer of aluminium material and aluminium cookware, and we have the whole line to produce aluminium coil and circles and aluminium cookware.