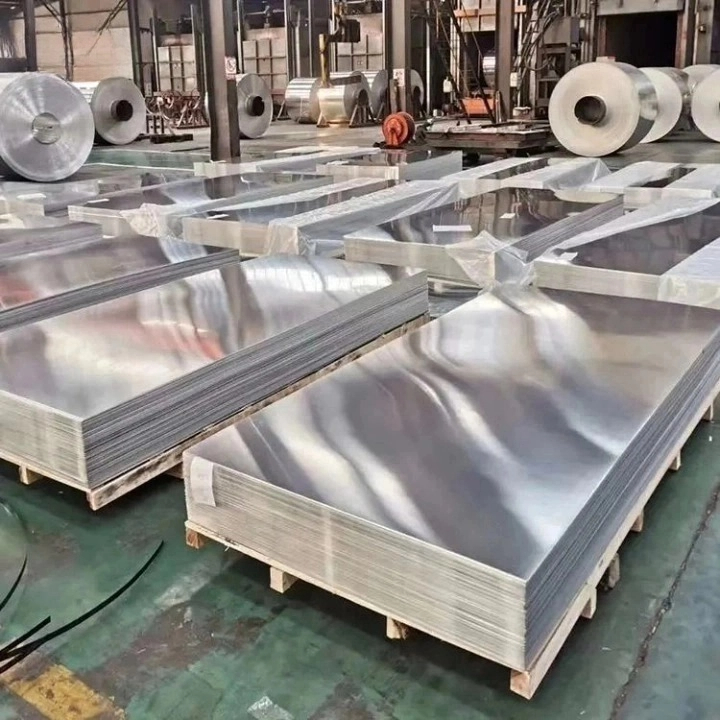

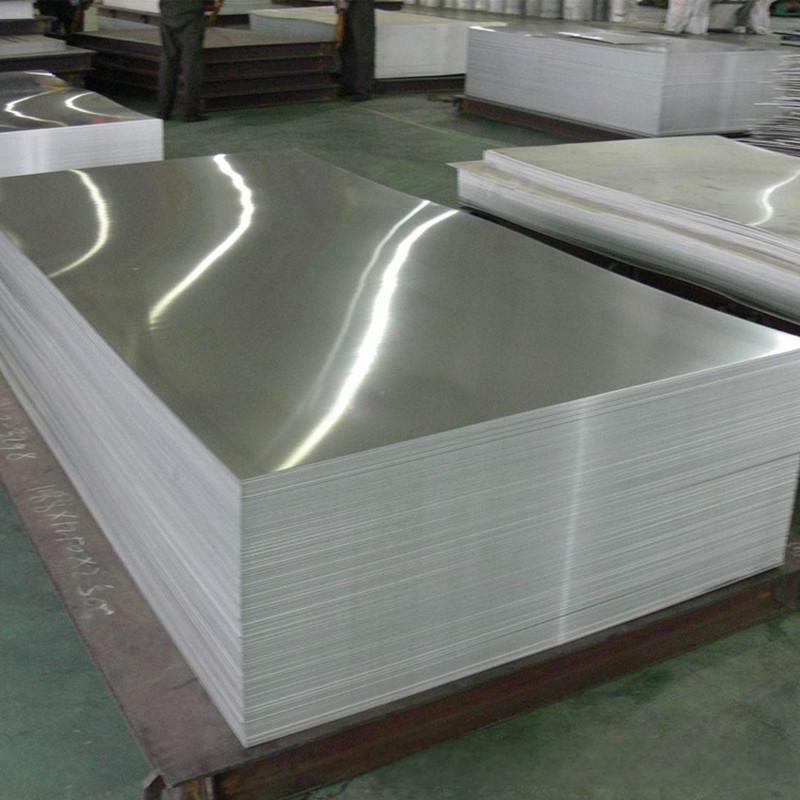

Hot Sale Aluminium Plate Products

Features of Aluminum Plate

Although similar to sheets, aluminum plates have a unique blend of features:

- Lightweight: Saves weight in airplanes, vehicles, and buildings.

- Strong: Offers a good strength-to-weight ratio, with some alloys achieving even higher strength.

- Corrosion Resistant: Naturally resists rust and can be further enhanced for outdoor use.

- Formable: Bends and shapes easily, perfect for complex designs.

- Conductive: Efficiently conducts heat and electricity for heat sinks, wiring, and cookware.

- Recyclable: Minimizes environmental impact.

- Machinable: Easy to drill, cut, and mill for precise parts.

- Aesthetics: Pleasant silver-gray appearance, paintable for customization.

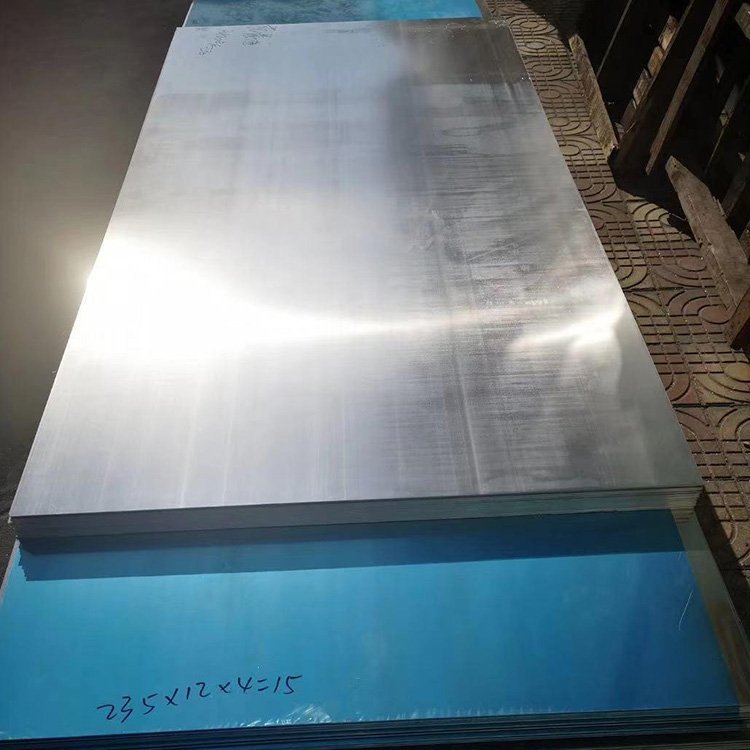

Specifications of Aluminum Plate

| Alloy Series | Alloy | Temper | Thickness (mm) | Width (mm) | Application |

| 1XXX | 1050 | O, H12 | 0.8 – 6.0 | 250 – 2000 | Electrical applications, decorative panels |

| 3XXX | 3003 | O, H12, H24 | 0.8 – 12.5 | 250 – 2000 | Building materials, signs, stamped parts |

| 5XXX | 5052 | H32, H42 | 0.8 – 6.35 | 250 – 2000 | Marine applications, tanks, sheet metal |

| 6XXX | 6061 | O, T4, T6 | 2.0 – 50.0 | 250 – 2000 | Building & construction, transportation, machinery |

| 7XXX | 7075 | T6 | 6.35 – 50.0 | 250 – 1000 | Aerospace, high-stress applications |

Application of Aluminum Plate

Aluminum plate is widely used in different industries due to its good performance in physical properties, some of which include:

| Aerospace Industry | Aircraft structures and components Fuselages and wings Spacecraft parts Missile components | Transportation | Railway carriages and components Truck and trailer bodies Bicycle frames Public transportation vehicles (buses and trains) |

| Automotive Industry | Body panels Engine components Wheels and chassis Heat exchangers and radiators | Defense and Military | Armor plating Military vehicles Weaponry and munitions Naval vessels |

| Construction | Roofing and siding Structural frameworks Doors and windows Architectural facades Bridges and infrastructure projects | Industrial Equipment | Machinery and equipment housings Conveyor systems Heat exchangers Industrial tanks and storage |

| Marine Industry | Shipbuilding and boat hulls Decks and superstructures Offshore platforms Marine fittings and equipment | Consumer Goods | Appliances and white goods Sporting goods and equipment Furniture and fixtures Cookware and utensils |

| Electrical and Electronics | Electrical enclosures and panels Heat sinks Circuit boards and electronic components Power transmission lines | Renewable Energy | Solar panel frames and mounts Wind turbine components Energy storage systems |

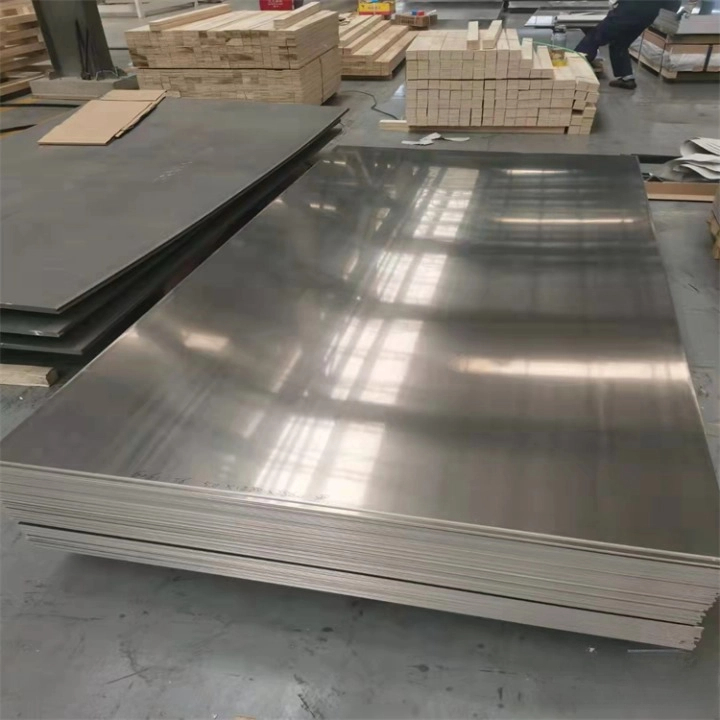

The Difference Between Aluminum Plate and Aluminum Sheet

Aluminum plate and aluminum sheet are essentially the same, with the primary difference being their thickness. The key difference between aluminum plate and aluminum sheet lies in their thickness.

Aluminum Sheet:

- Thickness: Typically ranges from 0.008 inches (0.2 mm) to 0.25 inches (6.35 mm).

- Applications: Sheet metal work, cladding, signs, flashing, fabrication of lightweight parts, and decorative applications.

- Characteristics: Thin, flexible, and relatively easy to bend and form.

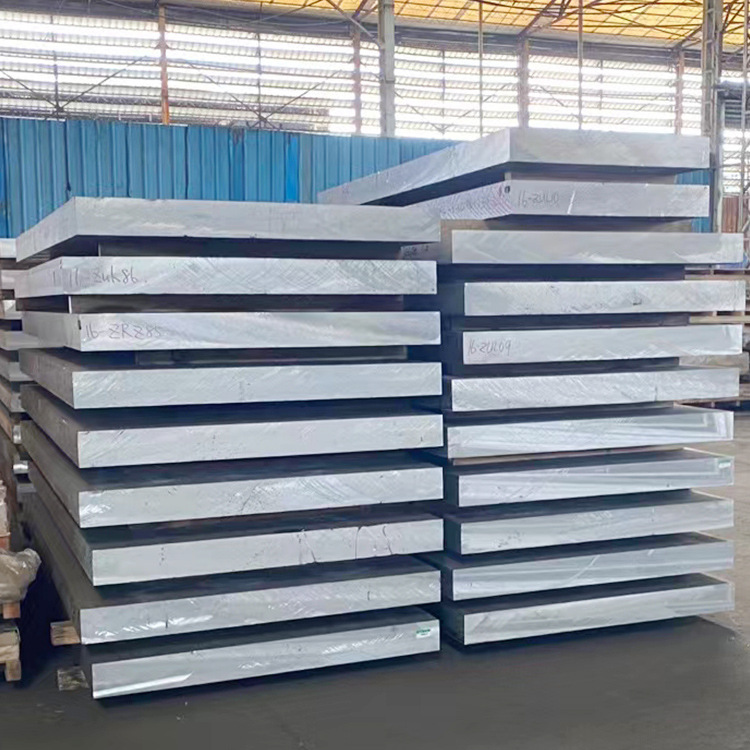

Aluminum Plate:

- Thickness: Generally starts at 0.25 inches (6.35 mm) and extends up to 6 inches (150 mm) or more.

- Applications: Structural components, machine enclosures, building panels, ducts, shipbuilding, pressure vessels, and applications requiring high strength and rigidity.

- Characteristics: Thick, rigid, and offers greater structural integrity compared to sheets.

Quality Control

To get good quality, Lanren strictly controls each step.

- Raw material: we produce aluminum plates by ourselves, and detect each batch, ensuring that all the products are pure and free of impurities. and the chemical composition meets customer requirements.

- Quality Assurance: Lanren aluminum plate is manufactured and controlled to international standards. Our products undergo stringent quality tests before they are dispatched.

- Material Testing: PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage-wise inspection from any of your representatives or third-party inspection agencies.

About Lanren Aluminium

Chongqing Lanren Aluminium Co., Ltd specializes in manufacturing aluminium materials and cookware. Our production capabilities encompass the entire range, from aluminum coils and circles to various types of cookware.

We offer a wide array of products including aluminium coils, sheets, circles, composite materials, cookware sets, fry pans, pie pans, baking trays, cake molds, and streamers. Additionally, we supply aluminium products tailored for specific needs such as deep drawing circles, induction circles, and color-coated circles.

We have established strong, long-term partnerships with over 80 countries worldwide, including the USA, Canada, Australia, Mexico, Spain, France, India, and South Africa. Upholding a commitment to quality and customer satisfaction, we provide high-quality products at competitive prices, backed by excellent after-sales service. We also offer OEM services to fulfill customized orders for our clients. We welcome you to visit our company and forge mutually beneficial business relationships!

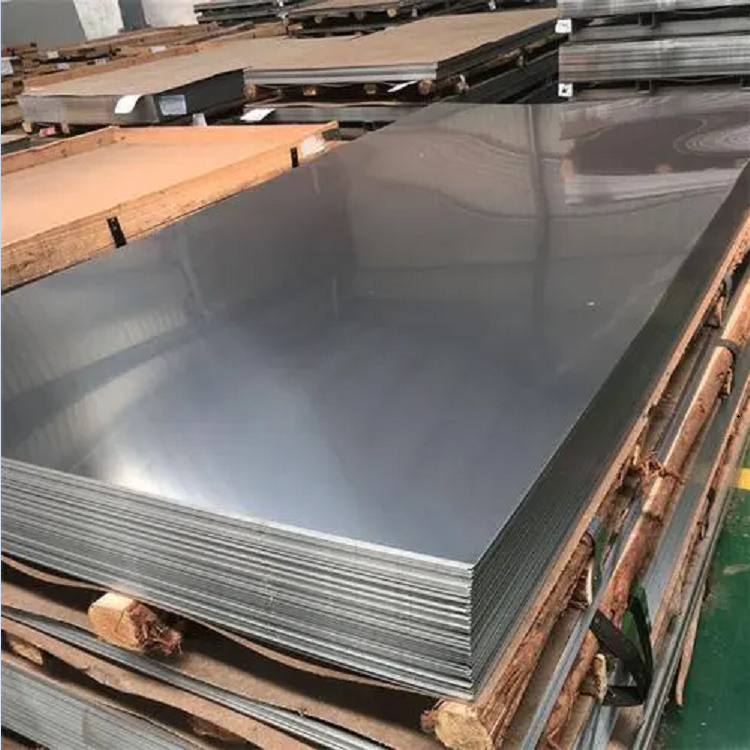

Aluminum Plate Packing and Transportation

- Standard airworthy export packaging. Wooden pallets with plastic protection for coils and plates;

- According to customer requirements, the packaging can face the sky or the wall;

- 16-20 MT can be put into 20FCL, the shipping price is much cheaper than 40FCL;

- Delivery time: 15-35 days after receiving the LC or 30% deposit.

Why Choose Us

Sample Services

We offer free samples for testing, with the customer covering the delivery charge.

Customized Services

We welcome customized samples and boast a professional design team to meet your requirements.

Processing Service

Our processing services include bending, decoiling, welding, punching, and cutting.

After-sales Service

We have professional after-sales service personnel who will receive your suggestions 24 hours a day.