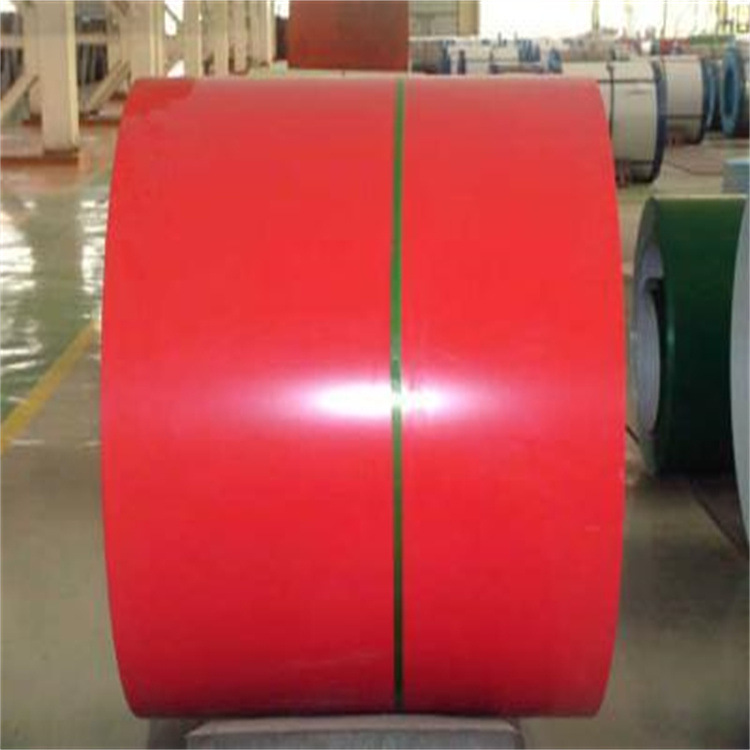

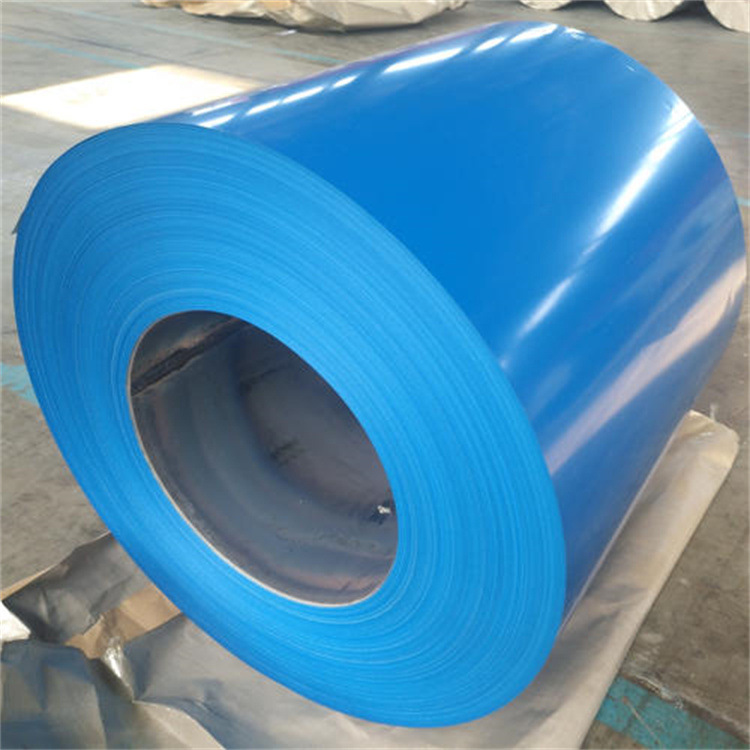

Polyester (PE) Coated Aluminum Coil

- Aluminum embossed coils also be known as embossed aluminum coils, are aluminum products that are rolled on the surface of aluminum coils to form various patterns and decorative patterns. Lanren Aluminum embossed coils are widely used in packaging, construction, curtain walls, freezers, interior decoration, ceilings, etc. According to the aluminum embossed coil thickness classification, can be divided into thin, medium, thick, ultra-thick, etc. The use space and scope of different standard aluminum embossed coils are different.

Product Description

- Our Polyester (PE) Coated Aluminum Coil is made from high-grade aluminum alloy, offering exceptional durability and resistance to corrosion. The specialized polyester paint coating provides excellent adhesion, flexibility, and UV resistance, ensuring long-lasting color and gloss even under extreme weather conditions.

- Available in various thicknesses and widths, our coils can be customized to meet specific project requirements. We offer different surface finishes, including smooth, matte, and high-gloss, to enhance the visual appeal of your projects.

- With a wide palette of colors, you can easily match your design vision, from classic neutrals to vibrant hues. The polyester coating provides strong resistance to weathering, chalking, and fading, making the aluminum coil ideal for both interior and exterior applications.

- Versatile in use, our PE-coated aluminum coils are perfect for building facades, roofing systems, ceilings, interior panels, signage, and even the automotive industry. Committed to sustainability, our coils are recyclable and manufactured using environmentally friendly processes, ensuring a safe and eco-friendly product.

Specifications of PE-Coated Aluminum Coil

| Aluminum Alloy | AA1100; AA3003; AA5005 |

| Coil thickness | 0.18mm,0.21mm,0.25mm,0.30mm,0.40mm,0.45mm,0.50mm |

| Coil width | 1240mm, 1270mm, 1520mm, |

| Coating thickness | Over 16 micro |

| Diameter | 405mm, 505mm |

| Coil weight | 2.5 to 3.0 tons per coil |

| Color | White series, metallic series, Dark series, Gold series( accept color customs) |

Advantages of PE Coated Aluminum Coil

Polyester (PE) coated aluminum coils offer several advantages, making them popular in various industries such as construction, automotive, and home appliances. Here are some of the key benefits:

- PE coatings provide excellent protection against the elements, making the aluminum coil resistant to UV radiation, moisture, and temperature fluctuations. This extends the lifespan of the material, even in harsh outdoor environments.

- The coating allows for a wide range of colors and finishes, providing aesthetic versatility. The high gloss and smooth surface achieved with PE coatings enhance the visual appeal of the aluminum coils, which is particularly important for architectural and decorative applications.

- The PE coating forms a protective barrier that prevents the aluminum from oxidizing and corroding. This is crucial for applications where the material is exposed to moisture or chemicals.

- PE-coated aluminum coils are generally more affordable compared to other coating materials like PVDF (polyvinylidene fluoride). This makes them a cost-effective solution for large projects and applications where budget constraints are a consideration.

- The smooth surface of PE-coated aluminum is easy to clean and maintain. It resists dirt and stains, requiring minimal upkeep to retain its appearance and performance over time.

- PE coatings adhere well to the aluminum substrate, ensuring that the coating remains intact during handling, processing, and installation. This strong adhesion contributes to the overall durability and longevity of the coated material.

Where Can PE Coated Aluminum Coil Be Used

PE-coated aluminum coil’s applications span a wide spectrum, from interior decor to exterior construction and beyond.

- For indoor use

Inside buildings, PE-coated aluminum coil shines as a wall covering option. Its smooth finish and diverse color palette lend themselves to contemporary interior design. Similarly, it’s a popular choice for ceilings, where it contributes to a sleek, modern aesthetic. Given its resistance to moisture and stains, it’s an excellent material for high-traffic areas like bathrooms and kitchens.

- For outdoor use

When it comes to external facades, PE-coated aluminum coil is a preferred material for cladding buildings. It provides a durable, attractive exterior while offering protection against the elements. Its weather-resistant properties also make it ideal for canopies and roofs. In architectural design, it serves as a versatile material for creating visually striking pillars and columns.

- For other use

Beyond building applications, PE-coated aluminum coil finds use in various industries. It’s a key component in aluminum composite panels (ACPs), large-format panels used in construction, signage, and interior design. The coil’s lightweight yet robust nature makes it an excellent choice for advertising signs, ensuring durability in outdoor environments. Moreover, it’s employed in the manufacturing of household appliances, providing a durable and visually appealing finish for panels and components.

The applicability of PE-coated aluminum coils is vast. Any application demanding a combination of strength, corrosion resistance, and aesthetic appeal is a potential fit for this material.

Lanren PE-Coated Aluminum Coil Quality Control

To ensure high quality, we must strictly control each step of the process.

- Raw Material: We produce PE-coated aluminum coil in-house and test each batch to ensure purity and absence of impurities. The chemical composition is verified to meet customer requirements.

- Quality Assurance: Our PE-coated aluminum coil is manufactured and controlled according to international standards. Each product undergoes stringent quality tests before dispatch.

- Material Testing: Our facility conducts various tests, including PMI testing, ultrasonic testing, mechanical testing, spectrochemical analysis, flaring tests, and IGC. We welcome stage-wise inspections from your representatives or third-party inspection agencies.