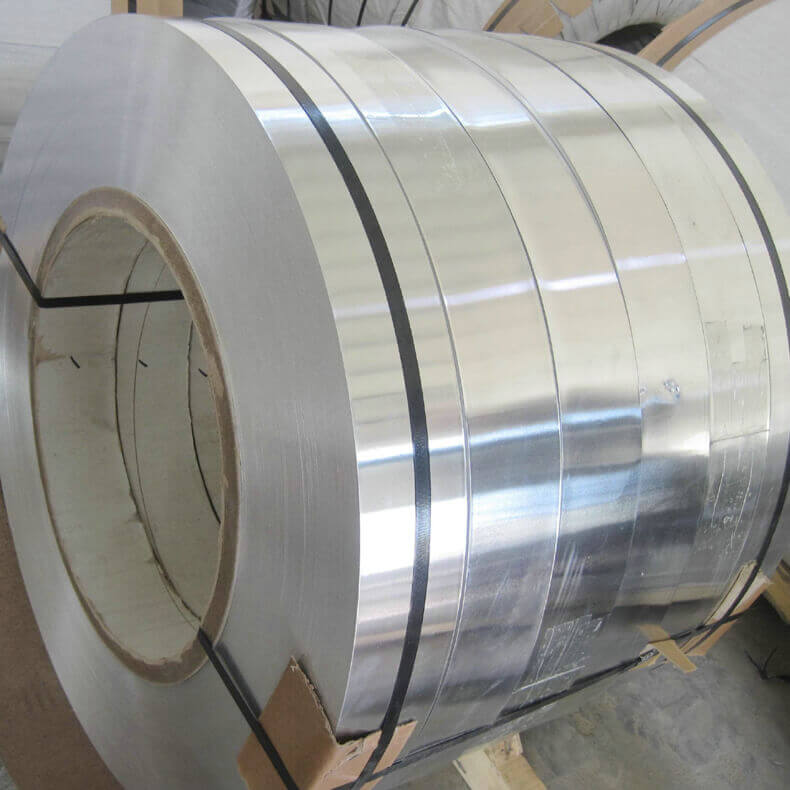

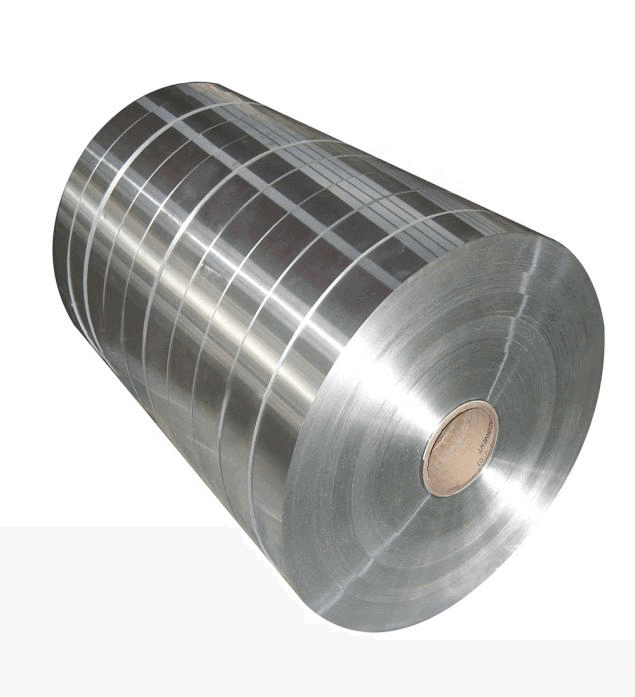

Mill Finish Aluminium Strip Roll

Lanren Aluminum provides a comprehensive selection of Pure Grade Mill Finish Aluminum strips. We use National standard ingots to ensure our products meet international quality benchmarks. Our aluminum strips are available in a diverse range of alloys, including clad composites. Whether you require standard dimensions or custom sizes, our stock can accommodate your specific needs. Our manufacturing adheres to leading global standards, with options for tighter tolerances or custom tempers upon request.

Product Description

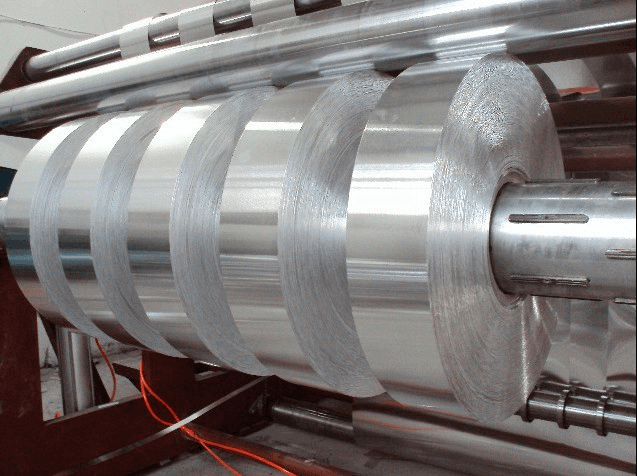

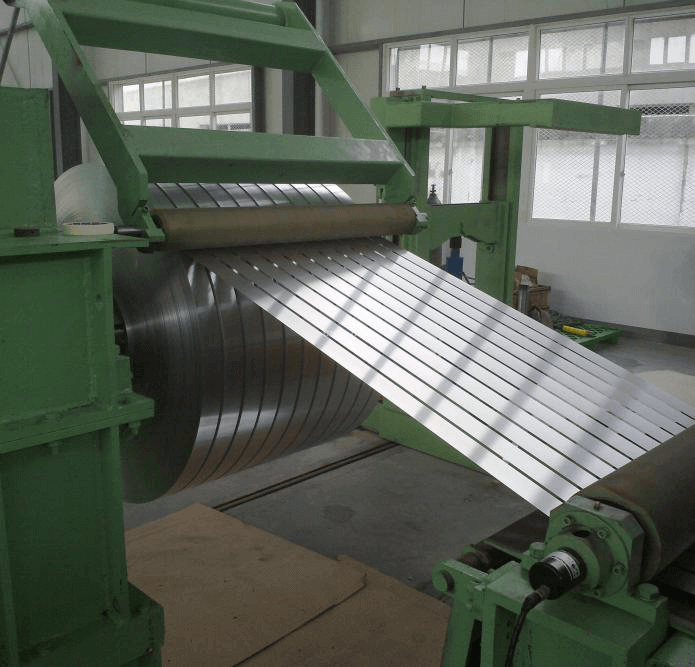

- Aluminum strips are produced by cold-rolling pure aluminum or aluminum alloy coils, which are initially cast-rolled or hot-rolled into aluminum coils of varying thicknesses and widths. These coils are then slit longitudinally into aluminum strips of different widths using a slitting machine. This process results in aluminum strips, a crucial material in various industries.

- Aluminum strips are categorized into different series based on the alloying elements they contain, with the 1000, 3000, 5000, and 8000 series being commonly used. These strips also vary in annealing states, such as full soft (O state), semi-hard (H24), and full hard (H18). The fully soft series (O state) is particularly popular due to its ease of stretching and bending.

- Lanren Aluminium spans nearly 50,000 square meters with over 300 employees, establishing itself as a comprehensive aluminum manufacturing enterprise in China. Renowned for its expansive production scale, advanced equipment, and diverse product offerings, Lanren Aluminium continues to lead in aluminum fabrication.

Specification of Mill Finish Aluminium Strip Roll

| Product | aluminium Strip |

| Alloy | 1050 1060 1100 1200 3003 3004 3105 5005 5052 8011 |

| Temper | O H12 H14 H16 H18 H22 H24 H32 T6 T651 T8 |

| Thickness | 0.15-4.00mm |

| Width | 10mm-915mm |

| Coil ID | 150mm 305mm 405mm 505mm |

| Lead Time | Within 30-45 days after receiving deposit |

| Packing | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

| Material | Using high-tech machinery utilizing premium grade aluminium Coil. |

| Surface | Bright & smooth surface, free from defects like white rust, oil patch, edge damage. |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | V | Others | Al |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.05 | / | / | 0.1 | / | / | 0.15 | 99 | |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | / | 0.05 | 0.03 | 0.05 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | / | 0.05 | 0.03 | 0.05 | 0.03 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | / | 0.04 | 0.03 | / | 0.03 | 99.7 |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | / | 0.15 | Others |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | / | / | 0.1 | / | / | 0.15 | Others |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | / | / | 1.15 | Others |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | / | 0.15 | Others |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.2 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | / | 0.15 | Others |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | / | 2.15 | Others |

Features of Mill Finish Aluminium Strip Roll

- High Purity: Made from high-quality, pure aluminum, ensuring superior performance and reliability.

- Smooth Surface: Provides an excellent, smooth finish ideal for further processing or as a final product.

- Versatile Applications: Suitable for a wide range of applications, including automotive, construction, electrical, and packaging industries.

- Corrosion Resistance: Offers strong resistance to corrosion, extending the lifespan of the end products.

- High Thermal and Electrical Conductivity: Optimal for applications requiring efficient heat and electrical conductivity.

- Customizable: Available in various thicknesses, widths, and alloy compositions to meet specific requirements.

Advantages of Mill Finish Aluminium Strip Roll

- Reflectivity: The high reflective surface of mirror aluminum coil sheets makes them ideal for applications requiring light reflection, such as lighting fixtures, solar reflectors, and decorative purposes.

- Aesthetic Appeal: The sleek, polished finish enhances the visual appeal, making it suitable for architectural and interior design applications where an attractive, modern look is desired.

- Corrosion Resistance: The mirror aluminum coil sheet is highly resistant to corrosion, ensuring longevity and durability in various environmental conditions.

- Lightweight: Despite its robustness and high durability, the mirror aluminum coil sheet is lightweight, making it easy to handle, transport, and install.

- Easy Maintenance: The smooth, polished surface of the mirror aluminum coil sheet is easy to clean and maintain, requiring minimal upkeep to retain its reflective quality and appearance.

Quality Control

To get good quality, we must strictly control each step.

- Raw material: we produce Mill Finish Aluminium Strip Roll by ourselves, and detect each batch, ensuring that the Mill Finish Aluminium Strip Roll is pure and free of impurities. and the chemical composition meets customer requirements.

- Quality Assurance: Mill Finish Aluminium Strip Roll is manufactured and controlled to international standards. Our products undergo stringent quality tests before they are dispatched.

- Material Testing: PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage-wise inspection from any of your representatives or third-party inspection agencies.