Mill Finish Aluminium Circle

- Alloy: 1050,1060,1070, 1100,1200, 3003, 3004,5052, 8011, etc.

- Temper: O, H12, H14,H16,H18,H22,H24,H26,H32, etc.

- Thickness: 0.4mm-10mm

- Diamters: 20mm-1380mm

- Application: kitchen utensils, stock pot, frying pan, rice cookers, lighting lamp, traffic sign, etc.

- MOQ:500kgs per size

- Certification: ISO9001/SGS/FDA

- Remarks: Specific requirements of alloy, temper, or specification can be discussed at your request.

Product Description of Mill Finish Aluminium Circle

Mill finish aluminium circles are specialized products that are mostly used in the production of cookware, traffic signals, lighting lampshade, gas containers, automobile brakes, and spinning. Our metallurgical processes ensure the availability of deep drawing quality specifications that match these demanding applications.

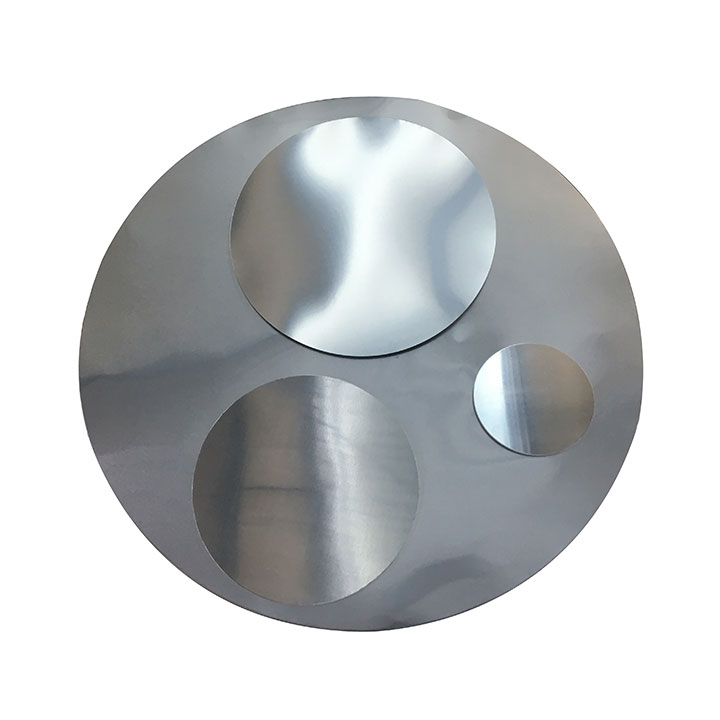

Our company strengthened the control of the grain size and elongation of the coil, Respectively cold rolled and hot rolled aluminum Discs sheet was launched, and covered 1, 3, 5, and 8 series alloys. Complete product range, thickness 0.4-10.0 mm, diameter 60 -1200 mm, tolerance and composition in line with national standard requirements. Two state-of-the-art disc blanking presses combined with open shear processing enable our facilities to supply a diverse range of markets.

Lanren Aluminium occupies an area of nearly 50,000 square meters and has more than 300 employees, and Lanren has become a comprehensive aluminum fabrication enterprise for its production scale, advanced equipment, and full-ranged product varieties in China.

Specification of Mill Finish Aluminium Circle

(1)Aluminium Discs detail

| Product | Mill Finish Aluminium Cirlces |

| Alloy | 1050 1060 1070 11002014 3003 4047 5005 5052 5454 6061 7075 8011 |

| Temper | O, H12, H14, H16,H18,H24,H32,H36 |

| Thickness | 0.4mm-10.0mm |

| Diameter | 60mm-1200mm |

| Type | CC & DC |

| Lead Time | Within 30-45 days after receiving deposit |

| Packing | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

| Material | Using high-tech machinery utilizing premium grade aluminium Circle. |

(2)Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | V | Others | Al |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.05 | / | / | 0.1 | / | / | 0.15 | 99 | |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | / | 0.05 | 0.03 | 0.05 | 0.03 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | / | 0.05 | 0.03 | 0.05 | 0.03 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | / | 0.04 | 0.03 | / | 0.03 | 99.7 |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | / | 0.15 | Others |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | / | / | 0.1 | / | / | 0.15 | Others |

| 4047 | 11月13日 | 0.8 | 0.3 | 0.15 | 0.1 | / | 0.2 | / | / | 0.15 | Others |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | / | / | 1.15 | Others |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | / | 0.15 | Others |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.2 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | / | 0.15 | Others |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | / | 2.15 | Others |

(2)Different alloy applications

| Alloy Series | Alloy | Typical Application |

| 1XXX | 1050 | Industrial device and storage vessel, tank, etc. |

| 1100 | ||

| 2XXX | 2014 | Aerospace structural parts, cabinet Shelley building and transportation vehicle, mechanical parts |

| 2024 | ||

| 3XXX | 3002 | Handling and storage device for chemicals, liquid transportation, curtain wall and radiator, pressure vessel and tubing, |

| 3004 | Production and storage device for chemicals, building panel, cable and tubing, etc | |

| 5052 | Metal sheet for marine and transportation vehicles, inner and outer siding, the board of railway carriage, the storage device of oil and chemical industry, equipment panel and medical machinery, etc. | |

| 5A02 | ||

| 5754 | Inner and out siding, bedplate and board of railway carriage, transportation, etc | |

| 5XXXX | 5086 | Board, siding and deck of ship side and bottom, etc |

| 5083 | Board, siding and deck of ship side and bottom, bedplate and board or railway carriage, welded parts of the ship, automotive and aircraft panel, cooling device, tower body of oxygen generator, structural parts of pressure vessel, tanker, oil storage tank and material storage tank of oil and chemical industries, mold for automotive tyre, etc. | |

| 5A05 | Ship structure, marine facilities, transportation tanker, pressure vessel and flange wiring board etc | |

| 5A06 | ||

| 6XXX | 6061 | Inner and out siding, bed plate and board of railway carriage, industrial moulding, automation mechanical parts, testing instrument, supporting plate of electronics jig and tool, equipment parts of semi-conductor, etc. |

| 6082 | ||

| 6063 | Bedplate of a commercial vehicle, roof framework, transporter and transship | |

| 7XXX | 7050 | Radar structural parts, manufacturing structure of aircraft, other high-stress structural elements wiki demand high strength and strong corrosion-resistance, etc. |

| 7075 | Aviation, aerospace, moulding, mechanical equipment, tooling and fixture, etc | |

| 8XXX | 8011 | Bottlecap/capsule, aluminum pilfer proof cap, lug cap, rip cap, screw cap, etc. |

Features of Mill Finish Aluminium Circle

- Use brand new aluminium ingots to produce a high-purity pure aluminum circle that meets your needs.

- There is a wide range of options in diameter 60-1200mm, thickness 0.4-10mm, and other sizes to meet your various needs.

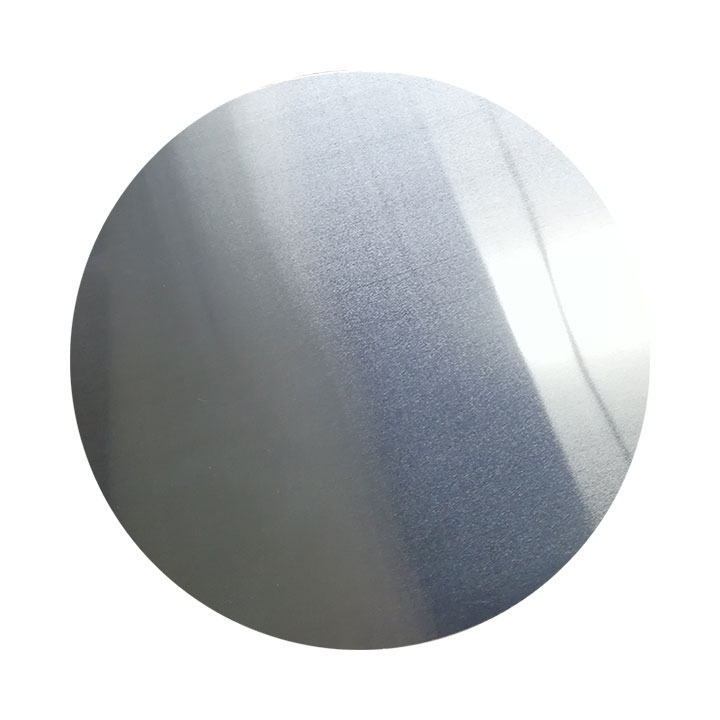

- The surface of the Discs is smooth, oil-free, with no burrs around, and high flatness.

- It can be coated and anodized in various colors, suitable for the manufacture of kitchenware.

- Product packaging firm, in line with domestic sales and international export standards.

- The good control of grain size and elongation in the early stage ensures that the aluminum circles of the deep drawing and spinning performance, effectively avoid the late processing that may occur when the drawing, lotus leaf, the ear rate of the high bad phenomenon, and can be used in the manufacture of cookware products, such as frying pans, sets of pans, high pans, non-stick pans and so on.

Advantages of Mill Finish Aluminium Circle

- Mill Finish Aluminium circles sheet specifications complete, conventional size outside, can provide the thinnest 0.4 mm, the thickest 10 mm aluminum Discs.

- Customized specifications are welcomed with a free mold fee.

- Mill Finish Aluminium circle surface performance is good, to ensure no obvious scratches, oil, oxidation, dark spots and so on.

- Aluminium Discs sheet thickness> 1.0 mm, to ensure that the finished side of the neat has no burrs.

- Strictly control the coil of the alloy, the state, and performance, to ensure the accuracy and diversity of aluminum Discs provided.

- The introduction of advanced and efficient production equipment improves the production efficiency of Mill Finish Aluminium Circle and the utilization rate of material and shortens the production cycle, providing real-time and convenient service for the customer.

- Products comply with ROHS and REACH the environmental protection standard.

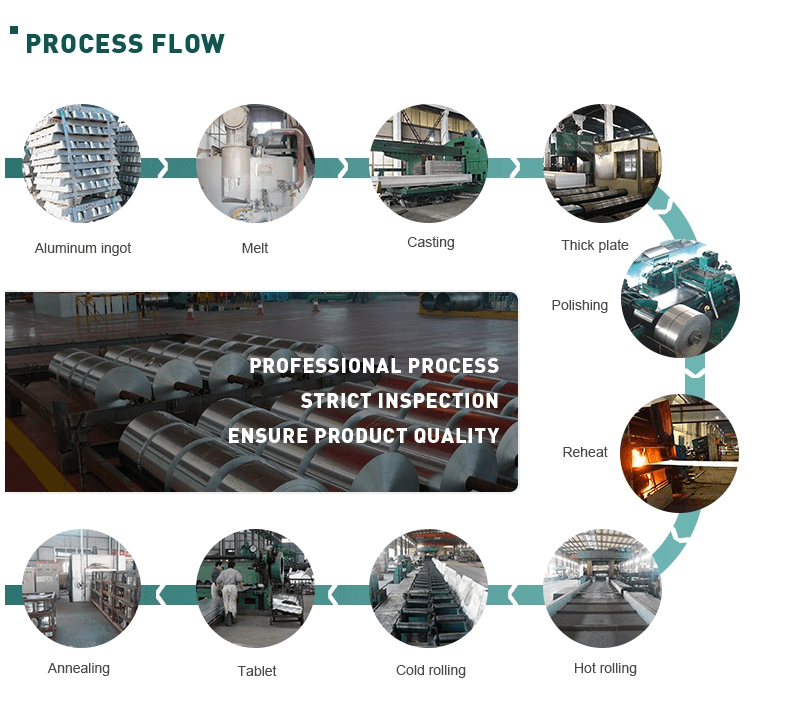

Product Process of Mill Finish Aluminium Circle

We have CC and DC materials, this is the difference between DC and CC materials

- Hot rolling process( Direct Cast rolling-DC): Aluminium ingot → Melting casting → Slag removal → Milling surface → Heating → Hot rolling → Cold rolling → Finishing rolling → Cut into Discs

- Casting and rolling process(Continuous Casting Rolling-CC): Melting casting → Crystal cooling forming → Cold rolling → Finishing rolling → Cut into Discs