How to Calculate the Weight of Aluminium Circles?

Calculating the weight of aluminium circles is essential for manufacturers, suppliers and customers who rely on precision in their projects. From cookware production to automotive component manufacture or industrial design projects – knowing exactly the weight helps ensure cost efficiency, logistics planning and structural integrity.

Why You Need to Calculate the Weight of Aluminium Circles

Understanding the exact weight of aluminium circles is crucial for efficiency and cost control across various industries. Manufacturing requires accurate weight calculations in order to order enough materials without an overstock or shortage that delays project delivery, while engineering/design applications rely on weight directly affecting structural integrity–especially aeronautical or automotive applications where every gram affects performance or fuel efficiency.

Logistics and shipping require accurate weight estimates in order to maximize freight costs while meeting transportation regulations, while industries like cookware production rely on consistent weights as quality control tools and safety requirements.

Miscalculations may lead to:

- Budget overruns from incorrect material orders

- Structural weaknesses in finished products

- Increased shipping costs due to weight discrepancies

Learning aluminium circle weight calculations is invaluable for time, cost, and project success. By understanding its weight ahead of time, production processes become more efficient and expenses can be cut while maintaining precision throughout every application.

Formula to Calculate Aluminium Circle Weight

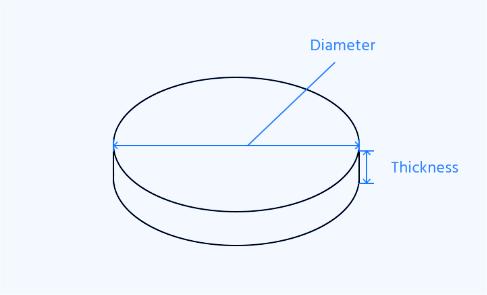

To determine the weight of an aluminium circle accurately, follow this formula:

Weight (kg) = π x diameter/2)2 x thickness and density of aluminium

Where:

π(Pi) = 3.1416

Diameter (D) = The width of a circle in millimeters.

Thickness (T) = Height of the circle in millimeters.

Density of Aluminium = 2.7 g/cm³ (or 0.0027 kg/cm³)

This formula calculates the volume of an aluminium circle and then converts it to weight using its density.

Step-by-Step Calculation

- Measure the diameter and thickness of the aluminium circle in millimeters.

- Find the radius by dividing the diameter by 2.

- Square the radius by multiplying it by itself.

- Multiply the squared radius by π (Pi ≈ 3.1416) to get the area.

- Multiply the area by the thickness of the circle.

- Multiply the result by the density of aluminium (2.7 g/cm³ or 2700 kg/m³).

- Convert the volume into weight by dividing by 1,000,000 to get the weight in kilograms.

Example Calculation

Let’s say you have an aluminium circle with:

Diameter = 300 mm

Thickness = 5 mm

Step-by-step:

Radius = 300 / 2 = 150 mm

Radius² = 150 × 150 = 22,500 mm²

Area = π × 22,500 ≈ 70,685 mm²

Volume = 70,685 × 5 = 353,425 mm³

Weight = 353,425 × 2.7 / 1,000,000 ≈ 0.954 kg

So, the weight of this aluminium circle is approximately 0.95 kg.

Factors Affecting Aluminium Circle Weight

Although basic weight calculations provide a reliable estimation, several key variables may alter their actual weights significantly, giving your project greater precision. Being aware of these potential variations ensures greater success:

1. Aluminium Alloy Composition

Aluminium alloys differ in terms of their chemical makeup and thus have different densities, giving rise to distinct density characteristics for each alloy type.

Example Alloys & Their Densities:

Pure Aluminium (1050, 1060, 1100): ~2.71 g/cm³

Al-Mg Alloys (5052, 5083): ~2.68 g/cm³

Al-Mg-Si Alloys (6061, 6063): ~2.70 g/cm³

Al-Zn Alloys (7075): ~2.81 g/cm³

When using alloys for critical applications, it is wise to confirm their exact density before proceeding.

- Thickness Variations

Even minor variations in thickness due to rolling tolerances can alter weight. Industry Standard Tolerances range from +-0.1mm to +-0.5mm depending on thickness; Pro Tip: For precise work, request mill-certified thickness measurements.

3. Diameter Precision

Cutting methods like laser, waterjet, or shearing can alter final dimensions slightly; larger diameters exacerbate even small measurement errors in weight calculations.

4. Surface Treatments and Coatings

Anodizing, painting, or any coating adds negligible but noticeable weight to surfaces; for instance, a 25mm anodized layer adds approximately 0.07 kg/m2.

5. Temperature Effects

Aluminium expands when heated (coefficient = 23mm/m*degC), although this rarely has an impactful weight calculation in room temperatures. Exceptionally significant in applications requiring thermal cycling, like aerospace applications, where thermal cycling occurs frequently.

For most commercial purposes, using the standard 2.7 g/cm³ density provides sufficient accuracy. However, for mission-critical applications, it is always prudent to verify alloy density as well as actual thickness with micrometers, and account for coatings or treatments applied over the top.

Aluminium Circle Weight Chart

Below is a practical weight chart for commonly used aluminium circles, based on standard density (2.7 g/cm³).

| Diameter (mm) | Thickness (mm) | Weight (kg) | Common Applications |

| 300 | 1 | 0.19 | Small cookware, lids |

| 500 | 2 | 1.06 | Automotive parts, signage |

| 800 | 3 | 4.07 | Industrial machinery, bases |

| 1000 | 5 | 10.6 | Large fabrication, structural components |

| 1200 | 6 | 18.3 | Aerospace, heavy-duty construction |

| 1500 | 8 | 38.2 | Shipbuilding, large-scale engineering |

Material Variations: Weights may slightly differ for 5052 and 6061 alloys (check density). Custom sizes should use either the formula above or consult their supplier to get accurate calculations. Utilise this chart to quickly estimate material needs – save it for your projects!

Need Custom Aluminium Circles?

If you require high-quality, precision-engineered aluminium circles tailored to your exact specifications, Lanren Aluminium is your ideal partner. As a leading manufacturer specializing in aluminium discs and circles, we provide a wide range of sizes, thicknesses, and alloys to meet diverse industrial needs.

We provide:

- Custom Sizes & Thicknesses – Ranging from small precision discs to large circles (up to 2000mm).

- Multiple Alloy Options Available – With 1050, 1060, 1100, 3003, 5052, 5083, and 6061 alloy options being readily available.

- Wide Applications – Perfect for cookware, lighting, automotive parts, machinery, and decorative industries.

- Strict Quality Control – Our products undergo stringent quality tests to ensure durability, corrosion resistance, and accurate weight tolerances.

- Competitive Pricing & Fast Delivery – Efficient production and global logistics support.

Whether you need mirror-finished, coated, or perforated aluminium circles, Lanren Aluminium delivers superior craftsmanship and reliability.

Contact us for more information about aluminium circles!

Related Products