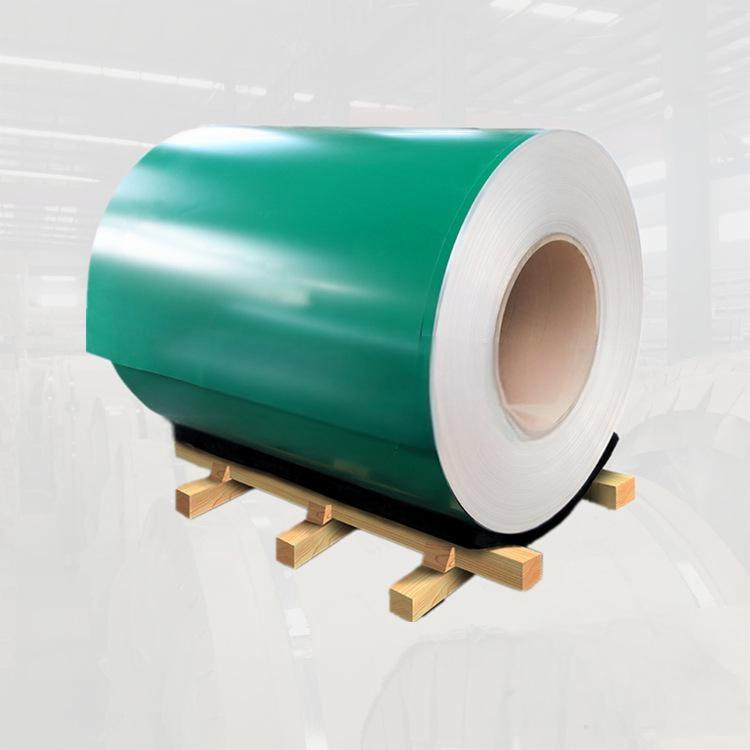

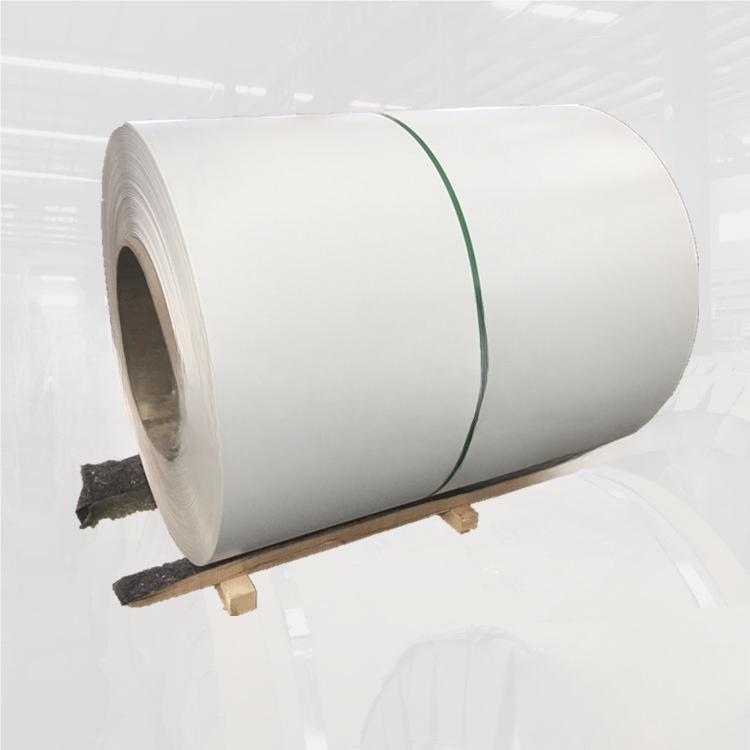

Fluorocarbon (PVDF) Color Coated Aluminum Coil

- Lanren Fluorocarbon (PVDF) Color Coated Aluminum Coil is a premium building material renowned for its exceptional durability and aesthetic appeal. Combining the strength of aluminum with the protective and decorative properties of PVDF coating, this product offers unmatched performance in various exterior applications.

- Engineered for longevity, the PVDF coating provides superior resistance to UV rays, corrosion, and pollution, ensuring the coil maintains its vibrant color and finish for decades. Its lightweight yet robust nature makes it ideal for a wide range of architectural projects.

What We Can Supply?

Lanren supplies high-quality fluorocarbon (PVDF) color-coated aluminum coils in various specifications to meet diverse customer needs. Our offerings include:

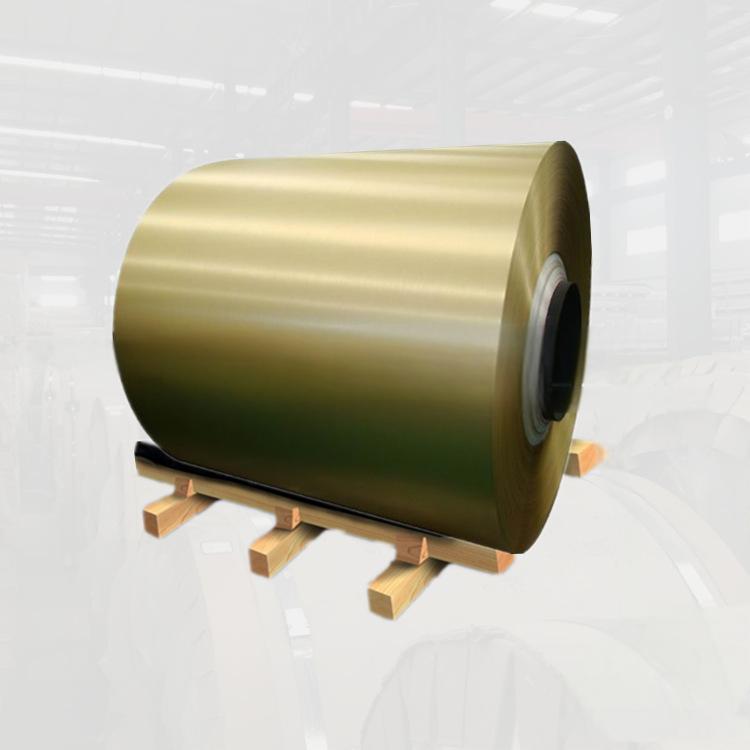

- A comprehensive range of colors and finishes.

- Customizable coil sizes and thicknesses.

- Consistent quality and prompt delivery.

- Technical support and expertise.

Specifications

- Alloy: 1000, 3000, 5000, and 8000 series

- Thickness: 0.02mm – 3.0mm

- Width: Up to 2000mm

- Coating Thickness: PVDF coating up to 25 microns

- Color: Available in a wide range of standard and custom colors

- Finish: Glossy, matte, metallic, and textured finishes available

- Core Material: High-quality aluminum core for superior strength and durability

Fluorocarbon (PVDF) Color Coated Aluminum Coil Advantages

- Fluorocarbon (PVDF) coating provides excellent durability, ensuring that the aluminum coil can withstand harsh environmental conditions. The coating resists chalking, fading, and cracking, maintaining its aesthetic appeal over time.

- PVDF-coated aluminum coil offers outstanding resistance to corrosion from pollutants, moisture, and chemicals. This makes it an ideal material for use in environments exposed to harsh weather or industrial pollutants.

- Available in a wide range of colors and finishes, PVDF-coated aluminum coil can be customized to match any design requirement. Its high gloss and smooth finish add a sophisticated touch to architectural projects.

- The PVDF coating provides superior protection against UV radiation, preventing color degradation and ensuring long-lasting vibrancy.

- Aluminum is a lightweight material, making it easy to handle and install. Its malleability allows for the creation of complex shapes and designs, offering flexibility in architectural and industrial applications.

Fluorocarbon (PVDF) Color Coated Aluminum Coil Applications

Fluorocarbon (PVDF) Color Coated Aluminum Coil is a versatile material used across various industries due to its durability, aesthetic appeal, and resistance to environmental factors. Key applications include:

- Building Facades: PVDF-coated aluminum coils are ideal for creating durable and visually appealing building exteriors. Their resistance to harsh weather conditions and pollutants ensures long-lasting performance, while the variety of colors and finishes available allows for creative architectural designs.

- Roofing Systems: In roofing, PVDF-coated aluminum coils provide excellent protection against UV radiation and weathering. Their lightweight nature facilitates easy installation, and the material’s energy-efficient reflective properties help in temperature regulation.

- Interior Design: Used in ceilings, wall panels, and decorative elements, PVDF-coated aluminum coils add a sophisticated touch to modern interiors. The material’s smooth finish and wide color range enhance aesthetic appeal, while its durability ensures long-lasting beauty.

- Transportation: The transportation industry benefits from PVDF-coated aluminum coils due to their lightweight and corrosion-resistant properties. They are commonly used in vehicle bodies and components, offering durability and a sleek appearance.

- Signage: PVDF-coated aluminum coils are perfect for outdoor signage that requires durability and vibrant colors. The material’s resistance to fading and corrosion ensures signs remain bright and readable over time.

- Industrial Uses: PVDF-coated aluminum coils are suitable for various industrial applications where resistance to harsh environments is crucial. They are used in the construction of equipment and machinery, ensuring longevity and reliability in demanding settings.

Lanren PVDF-Coated Aluminum Coil Quality Control

At Lanren, quality is our top priority. Our quality control process includes:

- Raw Material Inspection: Ensuring the highest quality aluminum and coating materials.

- Production Monitoring: Continuous supervision during the coating process to maintain consistency and quality.

- Final Inspection: Thorough testing and inspection of finished coils for color uniformity, coating adhesion, and overall appearance.

- Certification: Compliance with international standards and certifications, including ISO 9001 and ASTM.

Why Choose Lanren PVDF-Coated Aluminum Coil

- Experience and Expertise: Over decades of industry experience and a team of skilled professionals.

- Customization: Tailored solutions to meet specific project requirements.

- Innovation: Continuous investment in research and development to provide cutting-edge products.

- Customer Service: Dedicated support team ensuring a smooth purchasing experience from consultation to delivery.

- Competitive Pricing: High-quality products offered at competitive prices.