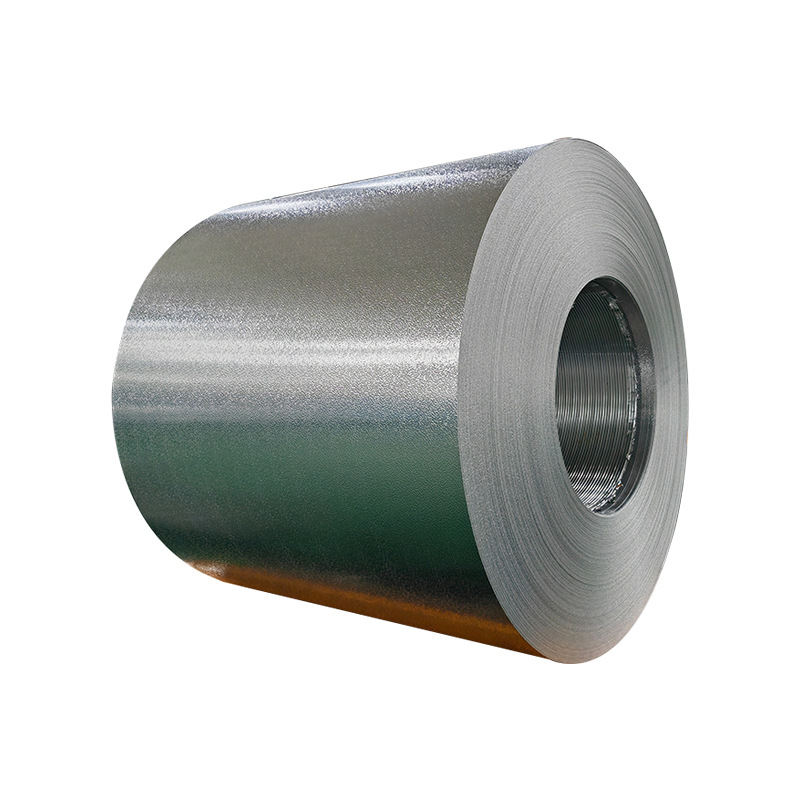

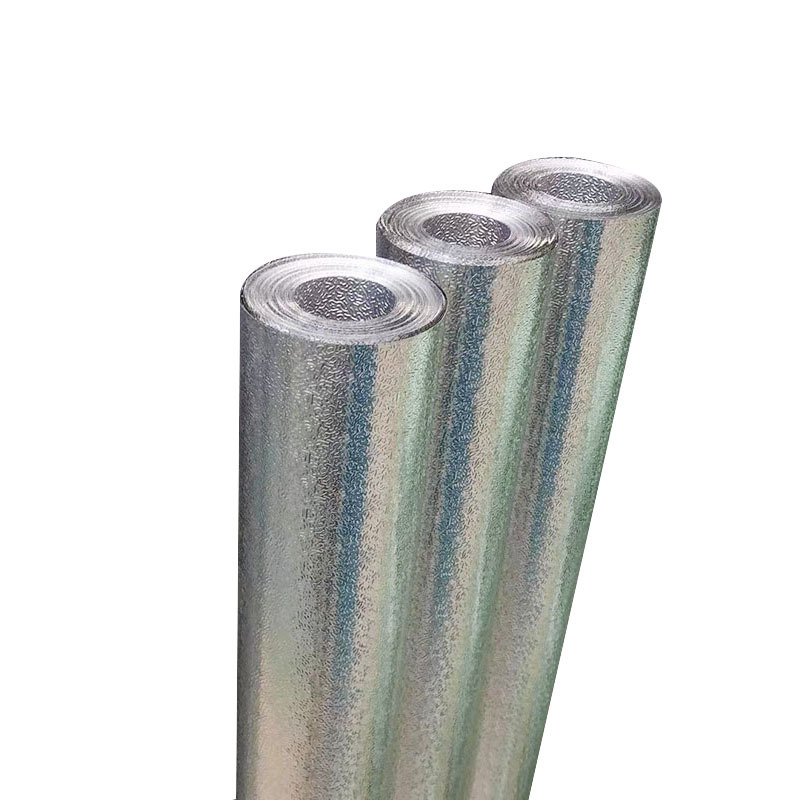

Embossed Aluminium coil

- Aluminum embossed coils also known as embossed aluminum coils, are aluminum products that are rolled on the surface of aluminum coils to form various patterns and decorative patterns. Lanren Aluminum embossed coils are widely used in packaging, construction, curtain walls, freezers, interior decoration, ceilings, etc. According to the aluminum embossed coil thickness classification, can be divided into thin, medium, thick, ultra-thick, etc. The use space and scope of different standard aluminum embossed coils are different.

Product Description

- The embossing technique involves printing on a smooth surface to create a raised pattern. Embossed aluminum coils are produced by hot melting the raw material, followed by cold rolling, surface treatment, and finally, cutting and embossing as per specific requirements.

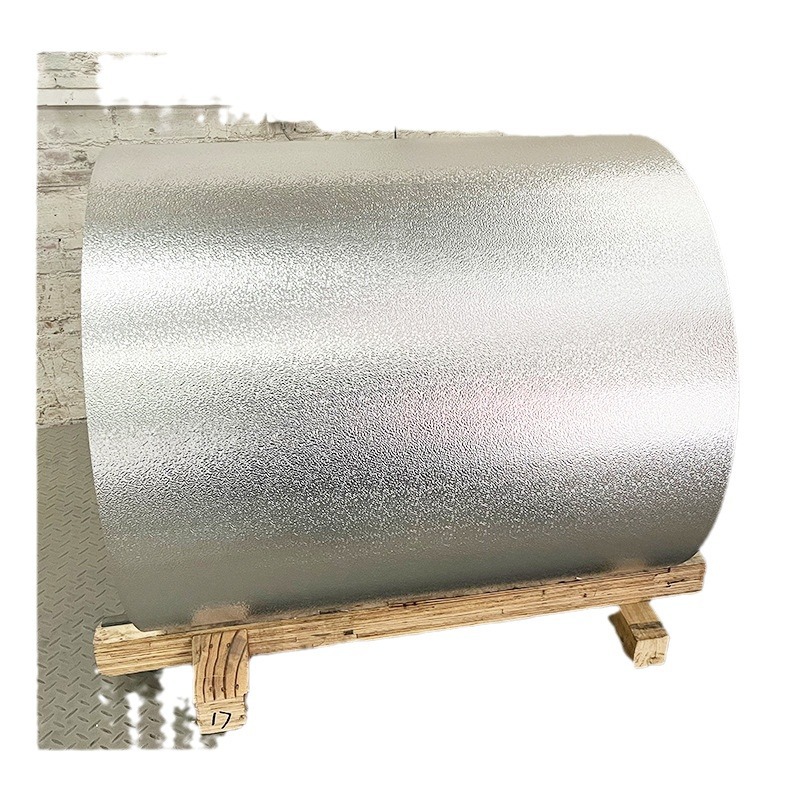

- The embossed aluminum coil finish is achieved by passing the natural mill finish material through embossing rollers. This process creates a surface that diffuses light, thereby reducing reflectivity and glare. These coils are used for decorative purposes or to minimize surface reflectivity.

- Due to their stability and durability, embossed aluminum coils are excellent for roofing or cladding applications without needing any protective coating. Over time, aluminum’s highly reflective surface will weather to a uniform patina finish when exposed to sun, wind, rain, and airborne sand and dirt. These changes in appearance will be consistent across the entire surface.

Specification of Embossed Aluminium Coil

- Embossed Aluminium Coil Detail:

| Product Name | Embossed Aluminium Coil |

| Alloy | 1050、1060、1070、1100、3003、3004、3105 |

| Temper | O,H12,H14,H16,H18,H22,H24,H26 |

| Minimum Order Quantity | 5000 Kilograms |

| Surface treatment | Stucco embossing |

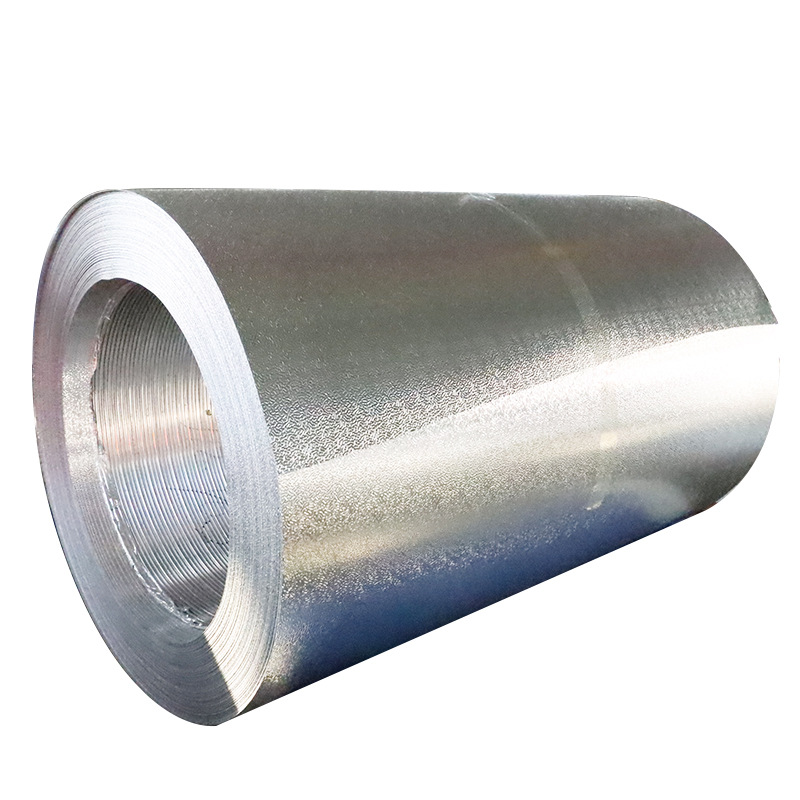

| Thickness | 0.2mm-3.0mm |

| Size/Dimension | Width 1000mm-1500mm |

| Coil | ID500/505/508/600mm, OD 1500mm Max. |

| Standards | ASTM-B209.EN573-1.GB/T3880 |

| Lead Time | Within 30-45 days after receiving deposit |

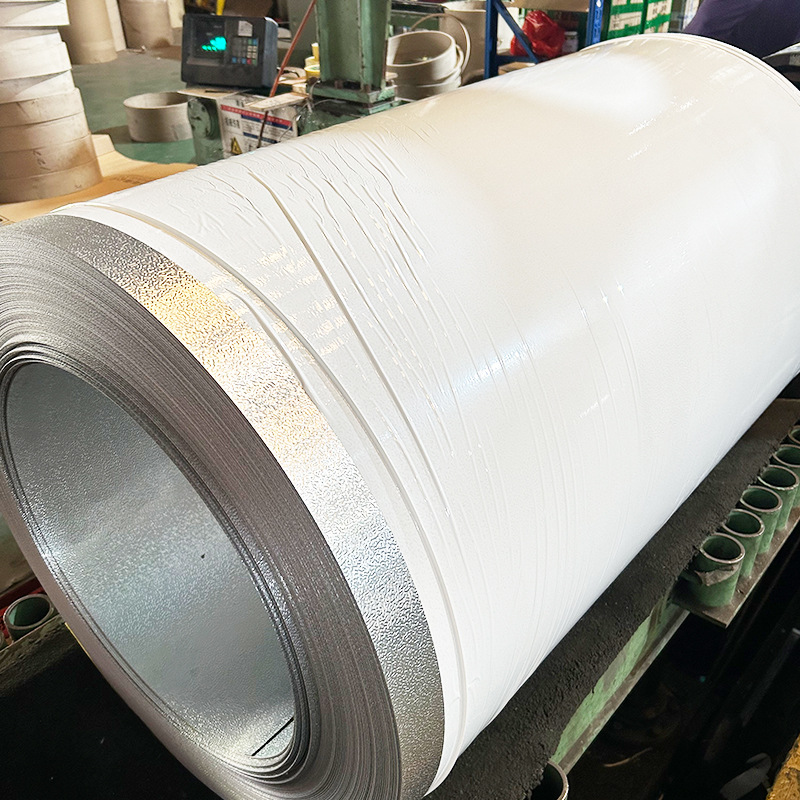

| Packing | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

- Composition (%)

| Chemical Composition(%) | ||||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others | Al | ||

| Standard | ≦0.95 | 0.05~0.20 | ≦0.05 | – | – | – | ≦0.10 | – | – | 99 | ||

| Notice: Aluminum foil does not contain Pb、As and other Virose elements | ||||||||||||

| Mechanical Property | ||||||||||||

| State | Tensile Strength(Mpa) | Strength(Mpa) | Elongation% | Cup Bulge | ||||||||

| Standard | H14 | 120~145 | _ | 2~3 | – | |||||||

Note: The data is for reference only.

Features of Embossed Aluminium Coil

Embossed aluminum coil boasts a unique combination of aesthetic appeal and functional benefits, making it a popular choice in various industries. Here’s a breakdown of its key features:

(1)Aesthetic Features:

- Visual Appeal: The embossing process creates raised patterns and textures on the aluminum surface, adding a decorative touch. This can enhance the visual interest of architectural panels, appliances, signage, and more.

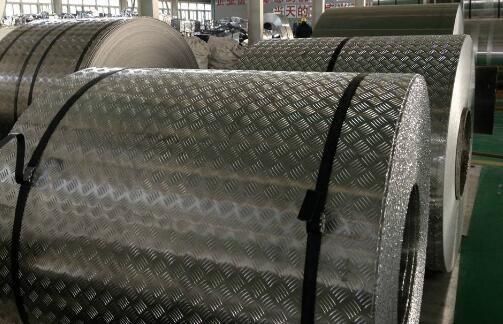

- Design Variety: Embossed aluminum coils come in a wide range of patterns, from classic like stucco and diamond plate to more modern options. This allows for design flexibility to suit various styles and applications.

(2)Functional Features:

- Enhanced Strength and Rigidity: The embossing process strengthens the aluminum sheet, making it more resistant to bending and deformation. This improved rigidity is valuable in applications requiring structural support, such as roofing and wall panels.

- Slip Resistance: The textured surface of embossed aluminum provides better grip, reducing the risk of slips and falls. This makes it ideal for flooring applications, particularly in areas prone to moisture or grease.

- Durability and Corrosion Resistance: Aluminum naturally resists rust and corrosion. Embossed aluminum coils often come with additional coatings like polyester paint, further enhancing their weather resistance and lifespan, especially for outdoor applications.

- Lightweight and Easy to Handle: Despite its increased strength, embossed aluminum remains lightweight. This simplifies handling, transportation, and installation, reducing overall project costs.

Overall, embossed aluminum coil offers a compelling combination of aesthetics, functionality, and practicality. When considering applications for architectural panels, appliances, signage, flooring, or even trim, embossed aluminum can be a versatile and valuable material to consider.

Quality Control

To get good quality, we must strictly control each step.

- Raw material: we produce Embossed Aluminium Coil by ourselves, and detect each batch, ensuring that the Embossed Aluminium Coil is pure and free of impurities. and the chemical composition meets customer requirements.

- Quality Assurance: Embossed Aluminium Coil is manufactured and controlled to international standards. Our products undergo stringent quality tests before they are dispatched.

- Material Testing: PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage-wise inspection from any of your representatives or third-party inspection agencies.

Packaging and Shipping