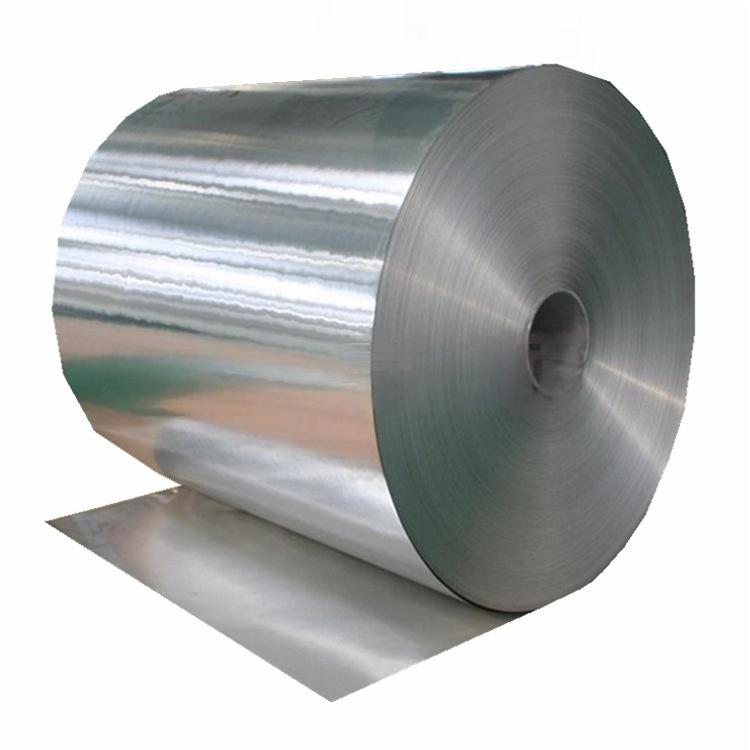

Anodized Aluminum Coil

- Lanren is an anodized aluminum coil supplier, able to carry out anodizing of aluminium coil rolls of varied surface treatment methods. We also supply relative products: ordinary mill finish anodized aluminum sheet coil, clear mirror finish anodized aluminum coil stock, brushed anodized aluminium coil, anodized embossed aluminum coil, etc. Custom service is also provided.

- Our huge inventory of anodized aluminum coils can satisfy large order requirements.

- Contact us now and let us start the journey of cooperation with high-quality anodized aluminum coil!

Product Description

- The Anodized Aluminum Coil is a versatile, high-performance material ideal for various industries. Its anodized finish offers exceptional corrosion resistance and durability, making it perfect for outdoor applications and environments exposed to harsh elements. Available in a range of vibrant colors and textures, it provides both aesthetic appeal and functional benefits.

- This coil maintains a high strength-to-weight ratio, crucial for automotive and aerospace industries, ensuring structural integrity without adding unnecessary bulk. Its malleability allows for easy forming and fabrication of complex shapes and components. Additionally, the Anodized Aluminum Coil is eco-friendly, as aluminum is fully recyclable and the anodizing process generates minimal waste.

- Overall, the Anodized Aluminum Coil combines aesthetic versatility, robust performance, and environmental sustainability, making it an excellent choice for modern industrial applications.

Specification of Anodized Aluminum Coil

| Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5005, 5052 |

| Temper | O,H12,H22,H14,H16,H18, H24,H26 |

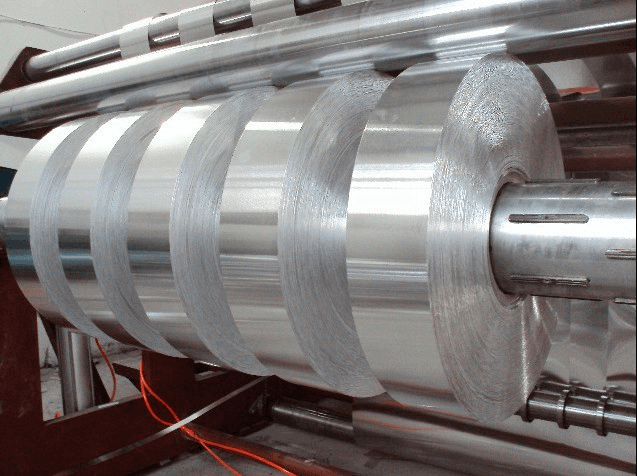

| Thickness | 0.2mm-8mm |

| Width | 100-2650mm |

| Surface treatment | mill finish, mirror finish, clear |

| Lead time | Within 30-45 days after receiving deposit |

| Payment terms | TT, LC, West Union, Kunlun Bank etc. |

Note: The data is for reference only.

Features of Anodized Aluminum Coil

Anodized aluminum coil offers several advantages over regular aluminum coil. Here are some key features:

- The anodization process creates a hard, protective oxide layer on the aluminum surface. This layer is significantly more resistant to scratches, corrosion, wear, and abrasion compared to raw aluminum.

- Anodizing significantly improves the aluminum’s resistance to corrosion, making it ideal for applications exposed to weather, moisture, or chemicals.

- The anodic oxide layer can be dyed or colored to achieve a wide variety of aesthetic finishes. This allows for customization beyond the natural aluminum look.

- The hard oxide layer provides excellent wear resistance, making anodized aluminum suitable for applications requiring frequent handling or friction.

- The anodic oxide layer acts as an electrical insulator, making anodized aluminum a good choice for applications requiring electrical isolation.

- The oxide layer enhances the ability of the aluminum to bond with paints, adhesives, and other coatings.

- Due to its enhanced resistance to corrosion and wear, anodized aluminum requires minimal maintenance compared to other materials.

Application of Anodized Aluminum Coil

Anodized aluminum coil, due to its combination of aesthetics, durability, and functionality, finds applications in a wide range of industries. Here are some key application areas:

| Industry | Application Examples | Key Features Benefiting Use |

| Building & Construction | Exterior cladding (facades, curtain walls, roofing) Interior design (wall panels, ceilings, trims) | Durability Weather resistance Variety of colors Ease of fabrication |

| Transportation | Automotive parts (trim, body panels, wheels) Marine components (decks, railings, hatches) | Lightweight Corrosion resistance Formability |

| Consumer Goods | Appliance components (refrigerators, ovens) Electronic casings (laptops, smartphones) Sporting goods (bicycle frames, skis) | Durability Aesthetics Heat dissipation Wear resistance |

| Industrial Applications | HVAC systems Machinery parts and enclosures | Lightweight Corrosion resistance Strength |

| Other Applications | Signage and displays Furniture components Certain aerospace applications | Weather resistance Lightweight construction Printability Strength-to-weight ratio |

Why Choose Lanren Anodized Aluminum Coil?

- Superior Quality and Durability

Anodizing creates a protective oxide layer on the aluminum surface, significantly enhancing its resistance to corrosion. This makes Lanren anodized aluminum coils ideal for use in harsh environments, ensuring longevity and reliability.

The anodizing process increases the surface hardness of aluminum, making it more resistant to scratches, abrasion, and wear. This is particularly beneficial for applications where the material is subjected to frequent handling or mechanical stress.

- Aesthetic Appeal

Lanren offers anodized aluminum coils in a variety of colors and finishes. The anodizing process allows for a consistent and attractive appearance, which can be tailored to meet specific design requirements. This makes it an excellent choice for architectural and decorative applications.

The colors achieved through anodizing are UV-stable and do not fade easily over time. This ensures that the aesthetic appeal of Lanren anodized aluminum coils remains intact even after prolonged exposure to sunlight and other environmental factors.

- Versatility and Customization

Lanren anodized aluminum coils can be used in a diverse range of applications, including construction, automotive, electronics, consumer goods, and more. Their versatility makes them suitable for both functional and decorative purposes.

Lanren offers customizable options in terms of thickness, width, and length of the Anodized aluminum coils, catering to specific project requirements. This flexibility ensures that clients receive products that are perfectly suited to their needs.

- Cost Benefits

Despite the premium quality, Lanren anodized aluminum coils offer a cost-effective solution due to their durability and low maintenance requirements. The extended lifespan of anodized aluminum reduces the need for frequent replacements, leading to long-term cost savings.