Anodized Aluminum Circle

- Alloy Or Not: Is Alloy

- Grade:1100/1050/1060/1070/1200/3003/3004/3005/3105/5005/5052/6061

- Packing: Export standard packaging: wooden pallet + cardboard + steel bar fixed

- Certification: ISO9001/SGS/FDA

- Application: Cookware/ Lighting industry/ aerospace /automotive applications

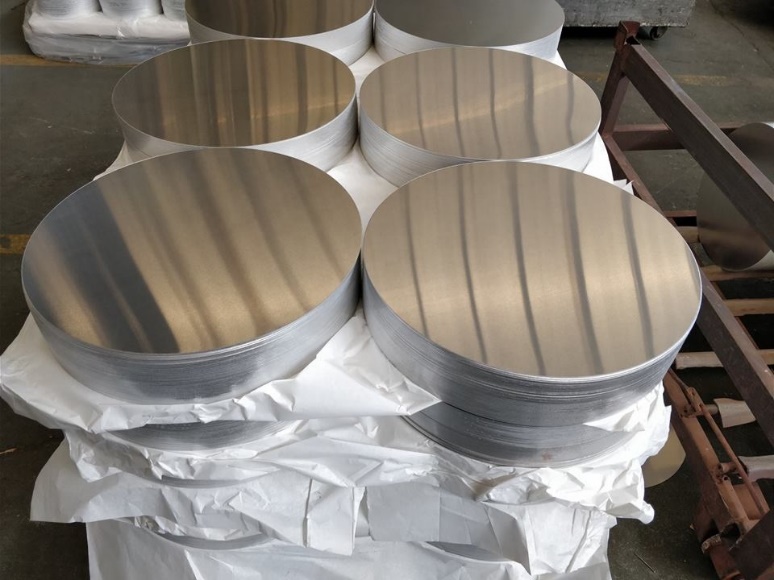

Anodized aluminum circles ( or called aluminum circles, aluminum discs ) is formed round shape blanks by stamping or cutting of anodized alloy metal aluminum sheet plate.

The aluminum circle anodizing process also has a production process, that is, anodizing. After anodizing, the hardness and corrosion resistance of the aluminum circle alloy will increase. Because aluminum alloy has no surface treatment and is easily oxidized by external factors, after anodized surface treatment, it can improve corrosion resistance, enhance wear resistance and hardness, and protect metal surfaces. Aluminum film has strong microporous adsorption capacity and is colored After being made into a variety of beautiful colors, it is favored by users. The typical application of anodized aluminum circles is advanced colored cookware.

Features of Anodized Aluminum Circle

- Strong corrosion resistance;

- Strong wear resistance

- Effectively improve hardness

- Strong impact resistance;

- Good surface gloss and easy maintenance

Advantages of Anodized Aluminum Circle

- Good processability: The anodized aluminum plate has strong decorative properties, moderate hardness, and can be easily bent and formed.

- Good weather resistance: the anodized aluminum plate does not discolor, corrode, oxidize, or rust after long-term use.

- Strong metallic feel: The surface hardness of the anodized aluminum plate is high, up to gem level, and has good scratch resistance. The surface is not covered by paint, retaining the metallic color of the aluminum plate, highlighting the modern metallic feel, and improving product quality.

The anodized aluminum circle has good anodizing effect, stable performance and high surface quality, which can be used to make high-end cooking utensils.

Specification of Anodized Aluminum Circle

| Place of Origin | CHINA |

| Brand Name | LANREN |

| Product | Anodized aluminum circle |

| Temper | O-H112 |

| Alloy Or Not | Is Alloy |

| Diameter | 60MM-1200MM |

| Thickness | 0.4mm-10mm |

| Grade | 1100/1050/1060/1070/1200/3003/3004/3005/3105/5005/5052/6061 |

| Surface Treatment | anodized |

| Packing | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

| Application | Cookware/ Lighting industry/ aerospace /automotive applications |

| Certification | ISO9001/SGS/FDA |

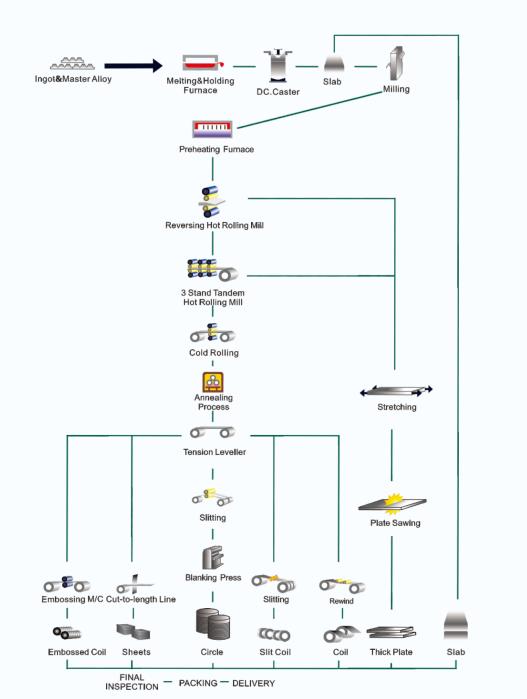

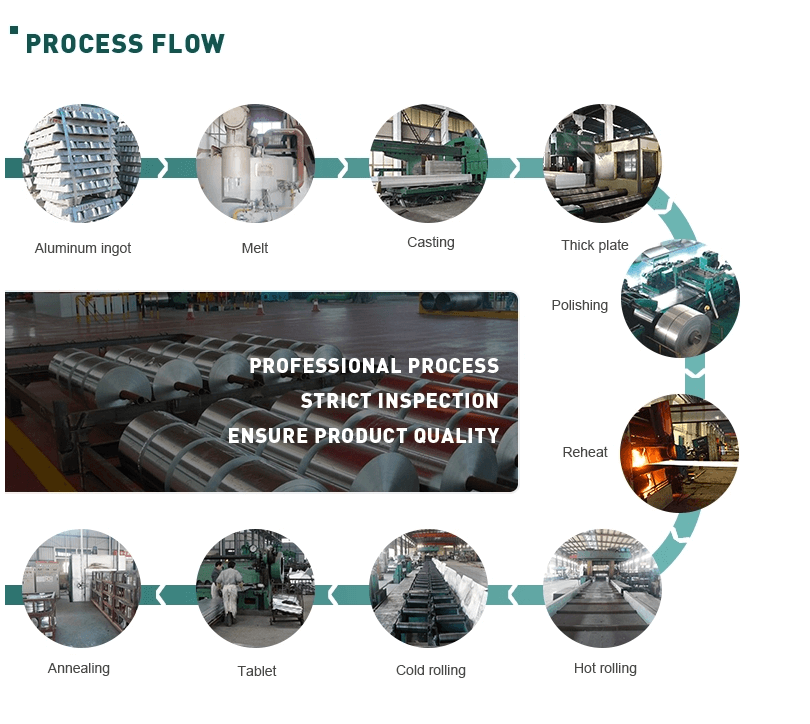

Product Process of Anodized Aluminum Circle

The production process for aluminum circles usually includes the following steps:

1. Melting casting: Heating aluminum ingots or waste aluminum to the melting point to melt it into aluminum water.

2. Refining: Remove impurities and gases from aluminum water to improve the purity of aluminum.

3. Casting: Pour the refined aluminum water into the mold, and get the aluminum round sheet blank after cooling and solidification.

4. Hot rolling: the aluminum sheet blank is heated to a certain temperature, and then hot rolling is carried out by the rolling mill to make its thickness thinner and diameter larger.

5. Annealing: the hot-rolled aluminum sheet is annealed to eliminate its internal stress and improve its plasticity and toughness.

6. Cold rolling: the annealed aluminum sheet is cold rolled to further thin its thickness and further increase its diameter to achieve the required size and accuracy requirements. 7. Surface treatment: the surface treatment of the cold-rolled aluminum sheet, such as cleaning, polishing, anodizing, etc., to improve its surface quality and corrosion resistance. 8. Inspection and packaging: Inspection of the surface-treated aluminum wafer to ensure that its quality meets the standard requirements, and then packaging and storage. It should be noted that different manufacturers and production processes may be different, and the specific production process should be adjusted and optimized according to the actual situation.

Why Choose Lanren?

- Our company has 15 years of experience.

- Free samples and small trial orders are acceptable.

- We have a professional technical team and a service team.

- Supply Aluminium material with different sizes and alloys.

- Stock material available.

Packing&Delivery

FAQ

Q1: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q2: How can we guarantee quality?

A: Always a pre-production sample before mass production; Always final Inspection before shipment.

Q3: What can you buy from us?

A: Aluminum Sheets, Aluminum Coils, Aluminum Strips, Aluminum Products.

Q4: Why should you buy from us not from other suppliers?

A: Our company has 15 years of experience, free samples and small trial orders are acceptable. We have a professional technical team and a service team. Supply aluminium material in different sizes and alloys. Stock material available.

Q5: What services can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES;

Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY;

Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow;

Language Spoken: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian.