Aluminum Foil for Transformers: Applications and Benefits

Transformers are essential components in electrical systems, facilitating efficient power distribution and voltage regulation. Aluminum foil has become one of the go-to materials used in transformer manufacturing due to its wide array of properties which make it suitable for various applications within transformers while offering numerous advantages over more conventional materials like copper. This article investigates why aluminum foil is utilized within this industry, its key applications, and their unique benefits.

Why Aluminum Foil Can Be Used in Transformers

Aluminum foil is widely utilized in transformers due to its excellent electrical conductivity, lightweight nature, and corrosion resistance. While copper has traditionally been the go-to material for transformer windings, aluminum can provide an appealing alternative in applications where weight and cost are critical considerations. Aluminum’s conductivity compares favorably with copper at about 61% but its lower density significantly reduces weight for an overall lighter transformer solution. Furthermore, Aluminum is more abundant and cheaper than copper making it an economically appealing alternative option.

Aluminum foil offers excellent thermal conductivity, which makes it an essential part of dissipating heat generated during transformer operation. Furthermore, its malleability enables it to be easily shaped into thin foils for winding applications or other uses. When exposed to air it forms an oxide protective layer, further improving durability and resistance against environmental factors.

Applications of Aluminum Foil in Transformers

Aluminum foil plays a pivotal role in the construction and performance of transformers, offering versatility and efficiency across various applications. Thanks to its properties such as high electrical conductivity, lightweight composition, and outstanding thermal management capabilities, aluminum foil makes an excellent material choice for various transformer components. Here are its key applications in transformers:

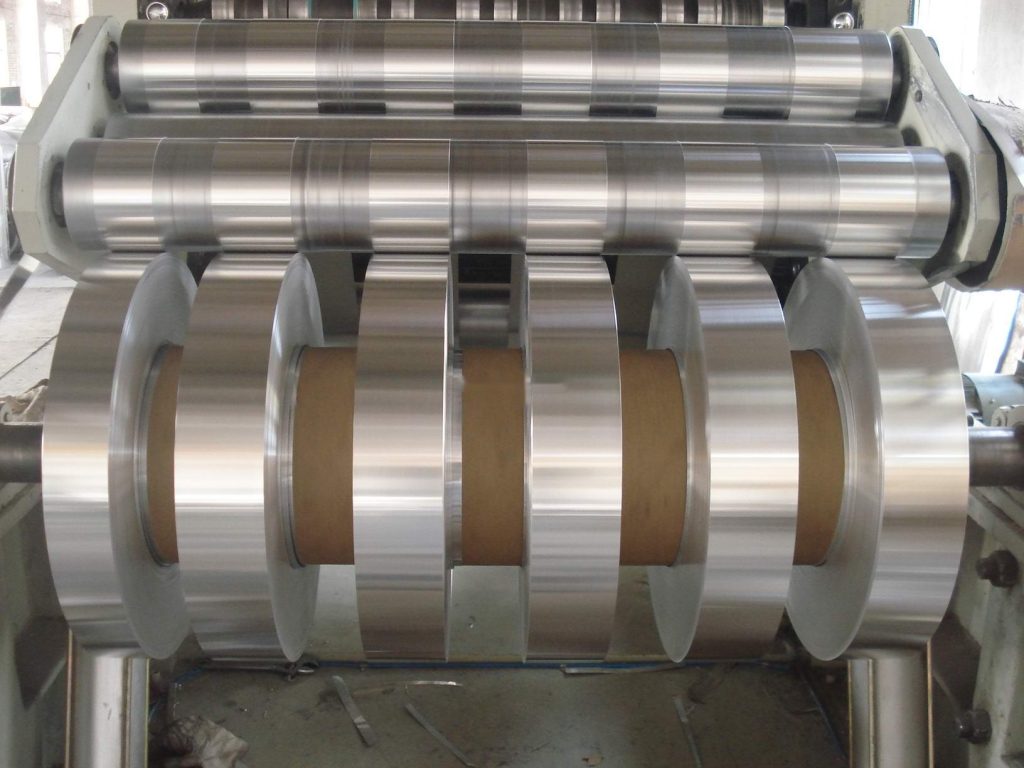

Aluminum Foil for Transformer Winding

Transformer windings are essential in transmitting electrical energy between circuits, and aluminum foil has become a popular choice as an efficient means of doing this. Aluminum foil’s excellent electrical conductivity minimizes energy losses while its light weight properties help minimize overall weight – both features that make aluminum foil particularly suitable in distribution transformer designs, where cost and weight savings are of the utmost importance. Furthermore, its easy installation makes aluminum foil an attractive solution to modern designs of transformers.

Thermal Management

Transformers produce heat while operating, so effective thermal management is vital to their performance and lifespan. Aluminum foil’s high thermal conductivity makes it an excellent material for dissipating it – often used in heat sinks, cooling fins, and other thermal management components to regulate temperature and prevent overheating. By efficiently dispersing it away from critical areas of a transformer’s operation, aluminum foil helps ensure it operates within safe temperature parameters.

Distributing Transformers

Space and weight constraints are always major limiting factors when designing distribution transformers, yet aluminum foil’s lightweight and flexible nature allows designers to craft more compact yet efficient transformers – something especially valuable in urban areas with limited space where installation and maintenance requirements must be minimalized quickly and effortlessly. Aluminum foil’s lightness enables manufacturers to produce smaller transformers without compromising performance; making these ideal candidates for modern power distribution networks.

Aluminum Foil for Core Shielding

The transformer core is responsible for channeling magnetic flux, and aluminum foil is often used to shield it in order to reduce electromagnetic interference (EMI), which may disrupt nearby electrical components and cause disruptions. By acting as a barrier against stray magnetic fields and improving efficiency and reliability of transformers. This application of foil shielding is especially crucial in sensitive environments where EMI must be controlled.

By taking advantage of aluminum foil’s properties manufacturers can produce transformers that not only perform efficiently and reliably but are cost-effective and adaptable across numerous applications.

Key Benefits of Aluminum Foil in Transformers

Aluminum foil offers many benefits that make it a suitable material for transformer applications, particularly cost-effectiveness. Aluminum is more cost-efficient than copper when manufacturing costs need to be kept under control without compromising performance – an attractive prospect when considering large-scale production, particularly distribution transformers where budget restrictions must be kept in mind.

- Aluminum’s lightweight nature makes it one of its main benefits, making transformers much lighter to transport, install, and maintain in urban or remote locations where handling heavy equipment may present difficulties.

- Aluminum foil also boasts superior corrosion resistance. When exposed to air, it forms a protective oxide layer which enhances its durability and longevity even under adverse environmental conditions. This ensures reliable performance over the lifespan of any transformer.

- Aluminum’s high thermal conductivity enables it to efficiently dissipate heat generated during operation and thus maintain optimal operating temperatures, thus avoiding overheating and prolonging transformer life.

- Aluminum foil is also an eco-friendly choice, fully recyclable, and meeting the demand for environmentally friendly materials in the electrical industry. By selecting this sustainable option, manufacturers can lower their environmental impact while still achieving top performance and reliability.

Aluminum foil offers numerous advantages for modern transformer applications, which offers numerous practical uses in transformer applications today and should be considered a viable and practical option.

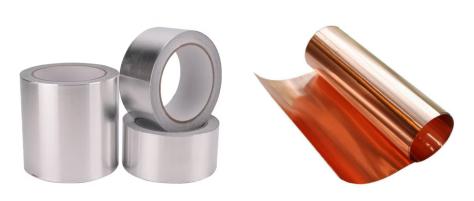

Aluminum Foil vs. Copper Foil in Transformers

The benefits of aluminum foil in transformers are clear, but how does it compare to copper foil, the traditional material of choice? Below is a comparison of the two materials based on key factors:

| Property | Aluminum Foil | Copper Foil |

| Electrical Conductivity | ~61% of copper’s conductivity | Higher conductivity (100%) |

| Weight | Lightweight (density: 2.7 g/cm³) | Heavier (density: 8.96 g/cm³) |

| Cost | More affordable | More expensive |

| Corrosion Resistance | Excellent (forms protective oxide layer) | Good, but prone to oxidation over time |

| Thermal Conductivity | High (effective for heat dissipation) | Slightly higher than aluminum |

| Sustainability | Highly recyclable and eco-friendly | Recyclable but less abundant |

Copper has the edge in terms of conductivity, while aluminum foil offers lighter and less costly designs that are resistant to corrosion – ideal for applications where weight and budget are of primary concern. Copper remains preferred for high performance transformer designs; however aluminum’s sustainability makes it a strong contender in modern transformer design; choosing which type depends on individual application needs that consider performance, cost and environmental considerations.

Conclusion

Aluminum foil has become an indispensable material in transformer manufacturing, offering many benefits that make it suitable for different uses in winding and core shielding, thermal management and compact design. From winding and core shielding to thermal management and compact design – aluminum foil plays a pivotal role in optimizing transformer performance and efficiency while its cost-effectiveness, lightweight nature and sustainability further cement its place as one of the go-to materials in modern transformer production.

By taking advantage of aluminum foil’s special properties, manufacturers can create transformers that not only meet modern electrical system demands, but are cost-effective and eco-friendly too.

Related Products