Aluminum Foil for Transformer

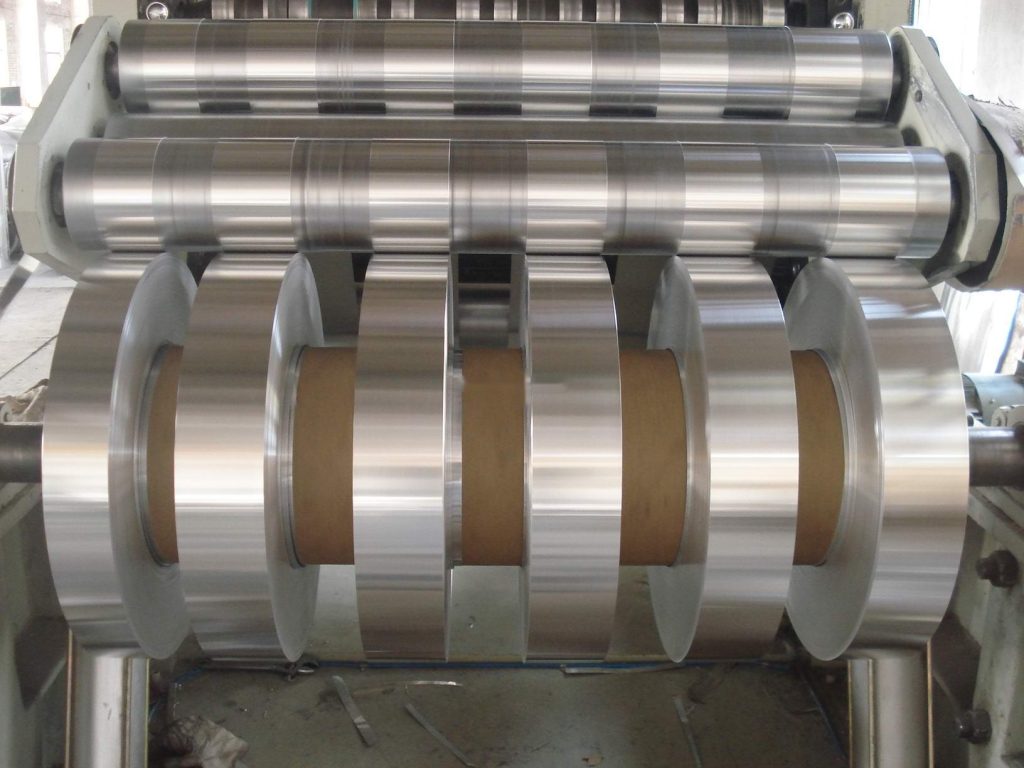

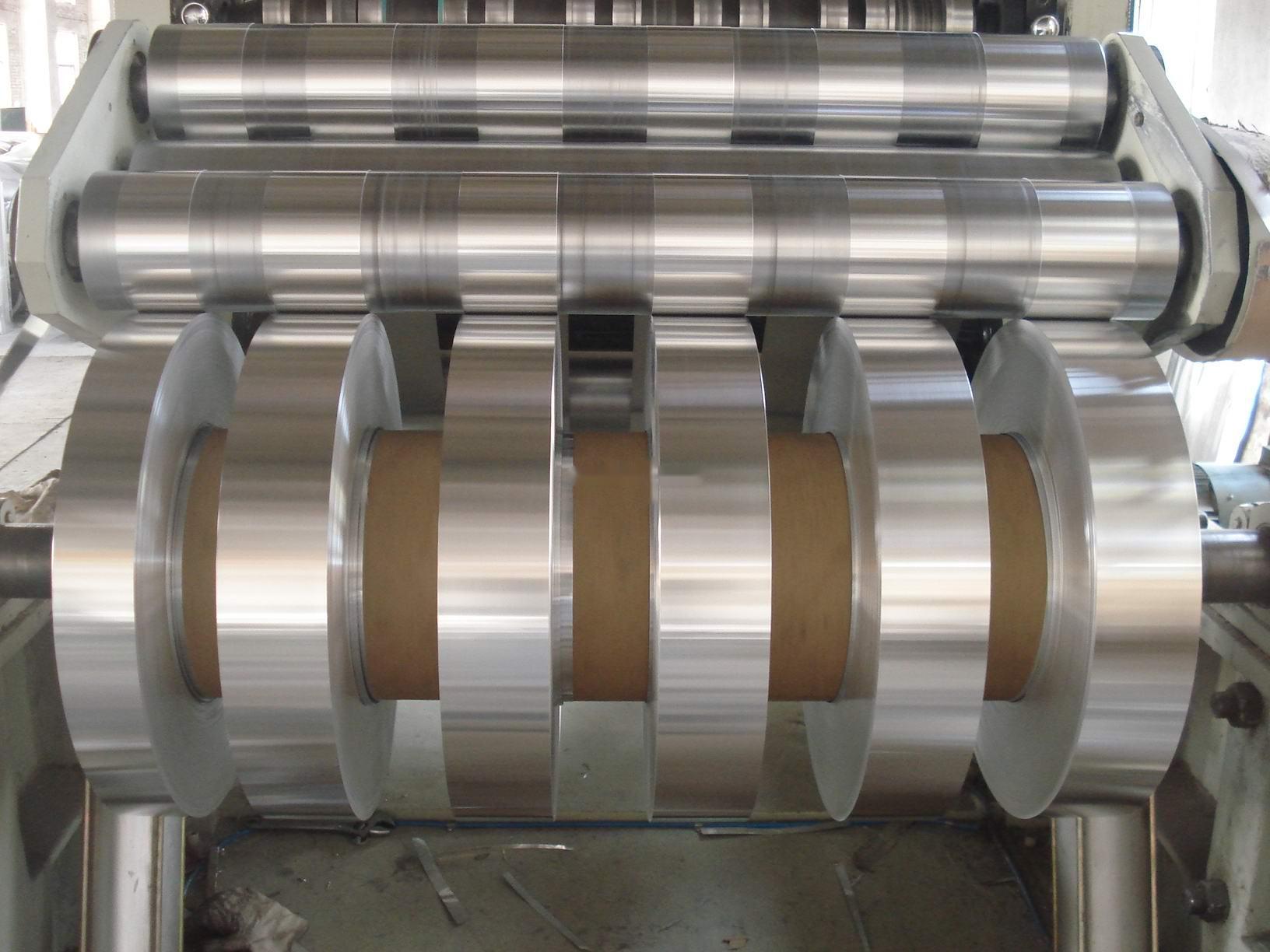

In transformers, aluminum foil is mainly used to make windings, especially in dry-type transformers. Aluminum foil for transformer winding has high purity and good conductivity, soft texture, smooth surface and no burrs, which can reduce cost and weight while ensuring transformer performance.

At Lanren aluminum, the thickness of aluminum foil for transformers is usually between 0.08-3mm, while the width can range from 20 mm to 1650 mm. These aluminum foils are usually made of 1060 aluminum sheet and strip as raw material. This aluminum sheet contains more than 99.6% aluminum and is called pure aluminum sheet. Feel free to contact us for your specific needs.

Specification of

| Alloy | Aluminum (Al) MIN | Silicon (Si) MAX | Iron (Fe) MAX | Copper (Cu) MAX | Manganese (Mn) MAX | Magnesium (Mg) MAX | Zinc (Zn) MAX | Titanium (Ti) MAX | Other Elements (Total) MAX |

| 1050 | 99.50% | 0.25% | 0.40% | 0.05% | 0.05% | 0.05% | 0.05% | 0.03% | 0.03% |

| 1350 | 99.50% | 0.10% | 0.40% | 0.05% | 0.01% | 0.01% | 0.05% | 0.01% | 0.03% |

| 1060 | 99.60% | 0.25% | 0.35% | 0.05% | 0.03% | 0.03% | 0.05% | 0.03% | 0.03% |

| 1070 | 99.70% | 0.20% | 0.25% | 0.04% | 0.03% | 0.03% | 0.04% | 0.03% | 0.03% |

| Alloy | 1050, 1350, 1060, 1070 |

| Temper | O |

| Thickness | 0.08mm-3mm or as required |

| Width | 20mm-1650mm or as required |

| Quantity Tolerance | ±10% |

| Surface Treatment | The foil has a smooth surface, free from scratches and impurities. |

| Electrical Conductivity | 1050, >60%ACS |

| 1060, >61.5%ACS | |

| 1070, >62.7%ACS | |

| 1350, >62%ACS | |

| Applications | Transformer winding |

| MOQ | 5 Tons |

| Payment Terms | TT, 100% LC at sight |

| Packaging | Wooden Pallet/Wooden Case |

The specific application of aluminum foil windings includes as materials for high-voltage windings and low-voltage windings of transformers.

In high-voltage windings, aluminum foil is wound with high-quality insulating foil and combined with resin through vacuum casting technology to ensure low partial discharge and good thermal stress management of the transformer. Low-voltage windings are wound with a single sheet of aluminum foil or copper foil, and the middle is insulated with resin-impregnated glass fiber cloth to provide additional electrical strength and structural integrity.

Advantages of

The main advantages of using aluminum foil in transformers include:

- Good electrical and thermal conductivity: Aluminum foil has high electrical conductivity, which can effectively transmit current, and has good thermal conductivity, which helps to dissipate heat and keep the temperature of the transformer stable.

- Lightweight: Compared with other conductors such as copper, aluminum has a lower density, so transformer aluminum foil is relatively light, which helps to reduce the weight of the transformer and facilitates transportation and installation.

- Corrosion resistance: Aluminum foil has good corrosion resistance and can work stably in the working environment inside the transformer for a long time.

- Cost-effectiveness: The price of aluminum is generally lower than that of copper, and using aluminum foil as a transformer winding material can reduce production costs.

- Resource sustainability: Aluminum is more abundant in the earth’s crust than copper and is easier to obtain, so using aluminum foil helps resource sustainability.