Aluminum Circle: the Best Material for Cookware

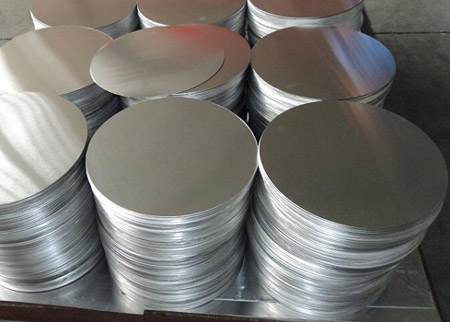

Aluminium Circle also named Aluminum Disc is widely used in electronics, daily chemicals, medicine, culture and education, and auto parts, Electrical appliances, heat preservation, machinery manufacturing, automobiles, aerospace, military, molds, construction, printing, and other industries. It is one of the deep-processed products of aluminum alloy plates with the largest consumption. In these applications, cookware is the most concentrated product of aluminum circles.

What is the Production Process of the Aluminum Circle?

At present, the final production method of the aluminum circle is to use the most advanced aluminum circle uncoiling blanking production line to produce an aluminum circle.

Such an automated production line is a fully automatic integrated aluminum circle production equipment, which can effectively improve the utilization rate of materials. The method of this automated production line is to use fully automatic integrated aluminum circle production equipment, which can effectively improve the material utilization rate. This production method is far superior to other aluminum circle production methods.

Put the aluminum coil into the aluminum circle uncoiling and blanking production line equipment. The aluminum coil will be automatically slit and cut, and the punching and blanking of the aluminum circle will be completed directly.

Aluminum Circle VS Other Materials. Which Material is Better for Cookware?

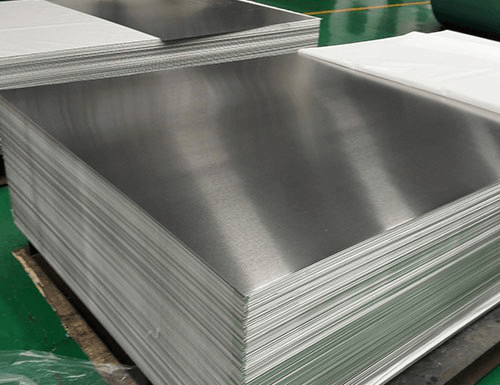

The materials for making cookware can be roughly divided into aluminum circles, stainless steel circles, and cast iron.

- Cookware Made of Aluminum Circle

The aluminum circle is light in weight and has good thermal conductivity, making it a popular choice for cooking. And the price of the aluminum circle is very cheap. Aluminum will not rust and can maintain resistance to all kinds of corrosion. It is a good choice for making cookware. And it usually takes only 4 minutes to process an aluminum circle into cookware. This kind of production efficiency is very high.

However, the raw aluminum circle plate is very reactive to alkaline or acidic foods, and it is easy to leave aluminum in the food during the cooking process. It is also very soft and easily warps and scratches at high temperatures.

- Cookware Made of Stainless Steel Circle

Stainless steel circle made from iron and other metals is strong and resists wear and tear. It is inexpensive, long-lasting, and the most popular cookware.

But more basic models usually have poor heat transfer and distribution. Moreover, the manufacturing process of the stainless steel circle is also more complicated. And it usually takes more time to process the circles.

- Cookware Made of Cast Iron

The material of the cast iron cookware is not a circle but is directly formed by casting iron. Cast iron is durable, inexpensive, naturally non-stick if properly seasoned, distributes heat evenly and retains heat well, imparts iron to foods (an added benefit for some), and is great for long, low simmering, and browning.

Iron pots and pans are more likely to be corroded, and the thermal conductivity is slower. Iron pans are not suitable for cooking acidic foods. In addition, it is heavy and requires more energy to clean and maintain.

Cast iron can be directly used as a material for cooking utensils, but its process is very complicated and requires cumbersome processing. Therefore, the price of cooking utensils made of cast iron is more expensive than that of cooking utensils made of aluminum discs.

Approximately 50% of the cookware in the world is made of aluminum circles!

When cooking, the heat efficiency of aluminum pots and pans is as high as 93%, while the heat efficiency of stainless steel circle and iron is only 1/3 of that of aluminum. When cooking, the heat efficiency of aluminum pots and pans is as high as 93%, while the heat efficiency of stainless steel circles and iron is only 1/3 of that of aluminum circles. And the price of the aluminum circle is cheaper than other materials.

This is why aluminum is widely used to make cookware.

How about the performance of the aluminum cookware made of aluminum circles?

First of all, we need to understand that the quality of aluminum cookware depends on the quality of the aluminum circle.

With the continuous update of material technology. Now use aluminum manganese alloy to make an aluminum circle. The cookware made of this aluminum circle retains all the physical and chemical properties of aluminum.

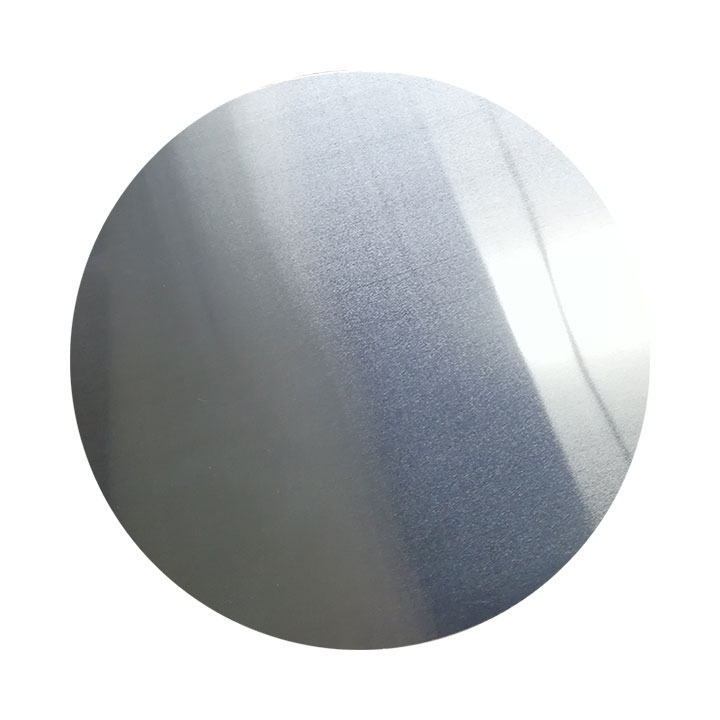

Nice appearance: Because the aluminum circle alloy is soft, it has strong ductility. It can be used to make various shapes of cookware. And after the product is formed, the surface particle size is uniform, the appearance is smooth, and the dimensional accuracy also meets the standard.

Better gloss In the manufacture of cookware, the aluminum-manganese alloy has no cracks. Because the shrinkage stress of the aluminum-manganese alloy does not exceed the bonding force of the metal crystal grains, the surface of each aluminum circle maintains a clear metallic luster.

Prevent corrosion: Aluminum circle also has excellent rust resistance and excellent corrosion resistance.

Because of these characteristics, the aluminum circle can become the best choice for cookware manufacturing among many metal materials.

High-quality Aluminum Circles to Make High-quality Aluminum Cookware!

Simply put, for the manufacture of high-quality aluminum cookware, aluminum circles with excellent performance are an indispensable manufacturing material. The quality of the aluminum circle determines the quality of the cookware.

Therefore, choosing a professional material supplier is a very important choice for a cookware manufacturing company.

We are a professional aluminum circle manufacturer that only provides high-quality aluminum circles. We have established long-term business ships with more than 80 countries and areas in the world, including the USA, Canada, Australia, Mexico, Spain, France, India, South Africa, etc. We can also offer OEM services to complete our client’s customized orders. If you have any needs, please feel free to contact us.