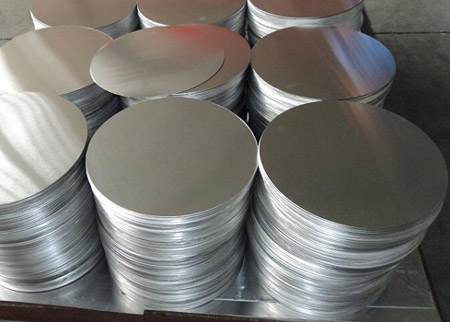

Aluminum Circle: Key Advantages for Cookware and Applications

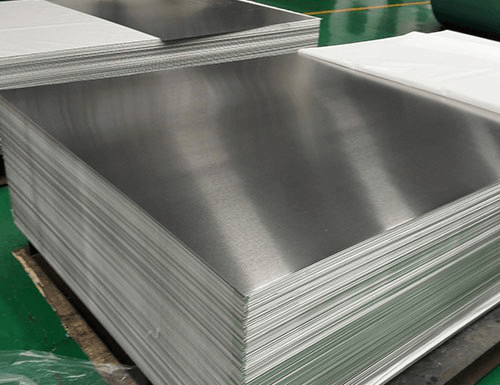

In cookware manufacturing, aluminum circle, or aluminum disc material stands out for its excellent properties, making it an ideal choice for kitchen applications. Lightweight, highly conductive, and cost-effective, aluminum round sheets are widely used in cookware manufacturing and other industries that require durable and efficient materials.

Aluminum Circle’s Advantage for Producing Cookware

According to incomplete statistics, about half of the cookware in the world is made of aluminum. The thermal efficiency of cooking is as high as 93%, while stainless steel and cast iron are only 1/3 of aluminum. Using aluminum discs to make cookware will greatly increase the physical and chemical properties of the cookware, so that the electrical conductivity, thermal conductivity, heat resistance and other properties of the cookware can be greatly improved, providing a guarantee for making delicious meals.

- Lightweight: Aluminum is lighter than traditional cookware materials such as stainless steel and cast iron, making the cookware more portable, especially suitable for outdoor activities and travel.

- Excellent thermal conductivity: Aluminum has excellent thermal conductivity and can transfer heat quickly and evenly, which can speed up cooking and improve energy efficiency.

- Mature processing technology: Aluminum discs can be processed into various shapes through processes such as stamping or casting, and the surface treatment technology is diverse, which can meet the design and functional requirements of different cookware.

- Good corrosion resistance: The oxide film formed on the surface of aluminum can protect the material from further corrosion, thereby extending the service life of the cookware.

- Environmentally friendly and healthy: Aluminum materials are environmentally friendly during production and use, and do not release harmful substances, which meets the health and environmental protection requirements of modern consumers.

- Diverse surface treatment: Aluminum discs can be anodized, sprayed and other surface treatments to enhance their wear resistance, corrosion resistance and decorativeness, meeting the aesthetic needs of different cookware.

- Rich resources and recycling: Aluminum is one of the metals with abundant content in the earth’s crust, and it is easy to recycle, which helps the sustainable use of resources.

- High production efficiency: Modern production equipment and technology can achieve high-efficiency production of aluminum discs, reduce waste and improve the utilization rate of raw materials.

These advantages make aluminum circles an ideal material for producing cookware, especially in modern kitchen appliances that pursue lightness, high efficiency and environmental protection.

Other Applications of Aluminum Circle

While aluminum circles are well-known in cookware manufacturing, their versatility and beneficial properties make them valuable in a wide array of industries beyond the kitchen. Here’s a closer look at some prominent uses of aluminum circles in other sectors:

Lighting Fixtures

Aluminum circles are frequently used in the lighting industry, especially in the production of reflectors and lamp shades. Their high reflectivity and lightweight nature make them ideal for:

- Reflectors for Industrial and Commercial Lighting: Aluminum circles are shaped and polished to create high-efficiency reflectors for lighting systems in warehouses, offices, and public spaces. These reflectors help direct light effectively, maximizing brightness while minimizing energy consumption.

- Outdoor and Street Lighting: Due to aluminum’ s durability and corrosion resistance, it’s commonly used in outdoor lighting applications where weather exposure is a factor. Aluminum circles are crafted into sturdy yet lightweight fixtures that can withstand varying climates while providing reliable illumination.

- Decorative and Architectural Lighting: Aluminum circles can be anodized or treated to add decorative finishes, making them suitable for high-end and custom lighting designs in hotels, theaters, and architectural installations. These treated aluminum components not only add aesthetic value but also increase the durability of the lighting fixtures.

Electronic and Electrical Applications

Aluminum circles are extensively utilized in the electronics sector due to their outstanding heat conductivity and non-magnetic characteristics, making them ideal for sensitive applications that require precise temperature control and stability.

- Heat Sinks: Aluminum circles are commonly used in the production of heat sinks, which are crucial for devices such as computers, LED lights, and power electronics. The high thermal conductivity of aluminum enables effective heat dissipation, preventing overheating and prolonging the life of electronic components.

- Transformer Windings and Capacitor Casings: In electrical systems, aluminum circles are utilized to manufacture casings for capacitors and windings in transformers. Aluminum’s lightweight nature and good conductivity allow these components to manage high electrical currents while keeping size and weight manageable.

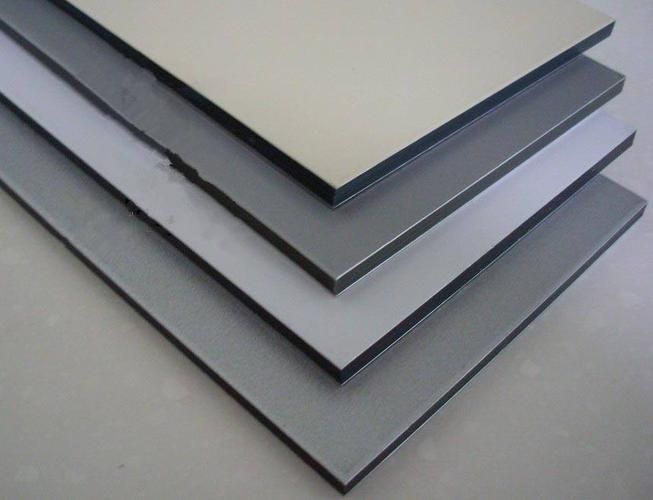

- Smartphone and Tablet Housings: Due to aluminum’s sleek appearance, light weight, and structural strength, many manufacturers use aluminum circles to create housings for tablets and smartphones. This not only imparts a premium feel and durability but also facilitates effective heat dissipation in electronic devices, enhancing the overall user experience.

Automotive and Industrial Components

Aluminum circles are essential in the automotive and industrial sectors, appreciated for their strength, lightweight properties, and effective heat dissipation. Key applications include:

- Brake and Clutch Components: In automotive braking systems, aluminum circles are used for components such as brake shoes and clutch discs. The lightweight yet robust nature of aluminum helps reduce the overall weight of vehicles, improving fuel efficiency and performance while ensuring safety.

- Fuel Tanks and Engine Parts: Fuel tanks constructed from aluminum circles leverage the material’s corrosion resistance and high strength-to-weight ratio, making them ideal for enduring wear and exposure to fuel. Aluminum circles are also utilized in manufacturing heat shields and other engine components that require efficient heat dissipation.

- Industrial Machinery and Equipment: Within manufacturing plants and heavy machinery, aluminum circles are incorporated into parts designed to withstand high heat and pressure. Their heat-resistant properties make them particularly valuable for components like pistons, pumps, and heat exchangers, where maintaining optimal temperature regulation is crucial for operational efficiency.

These diverse applications underscore the adaptability and usefulness of aluminum circles in both industrial and consumer settings. Their unique properties—high thermal and electrical conductivity, durability, and light weight—allow aluminum circles to meet the specific demands of multiple industries, providing a versatile and sustainable material choice for modern manufacturing.

Choose A Reliable Aluminum Circle Manufacturer

Choosing the right aluminum circle manufacturer is essential to ensure the quality and reliability of the final products. Here are some key factors to consider:

- Quality Standards: Look for manufacturers that adhere to international quality standards such as ISO certifications to guarantee high-quality materials.

- Customization Capabilities: Reliable manufacturers, like Lanren Aluminum,should offer a range of customization options, including size, thickness, and anodizing treatments, to meet specific requirements.

- Production Capacity: Manufacturers with high production capacity can often deliver large orders on time and provide consistent quality, which is especially important for businesses with high demand.

- Experience and Reputation: A well-established manufacturer with a good reputation is more likely to provide high-quality aluminum circles and reliable customer service.

Working with a trusted manufacturer can make a significant difference in the quality and performance of the aluminum circles used in your products.

Taking Advantage of Aluminum Circles

Aluminum circles provide unique advantages across a range of applications, from cookware and lighting fixtures to automotive and electronics components. Their combination of heat conductivity, durability, and affordability makes them an ideal choice for manufacturers looking to create high-quality, cost-effective products. By Choosing Lanren, you can fully leverage the benefits of aluminum circles, delivering products that meet high standards in both performance and design.

Welcome to contact us for more information!