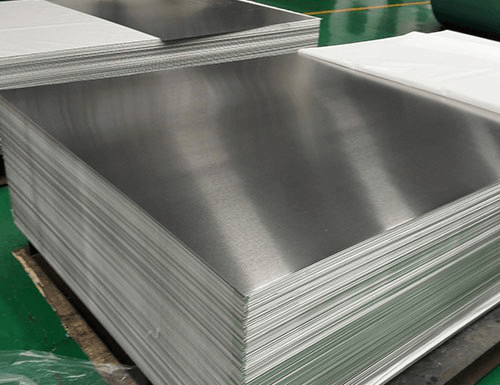

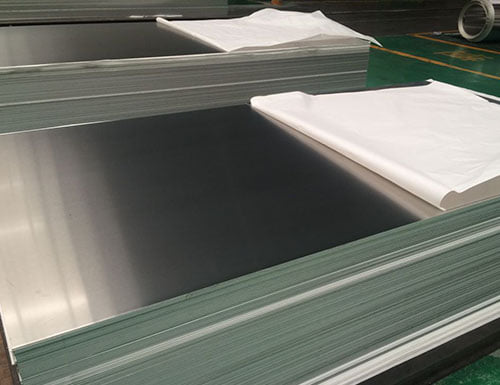

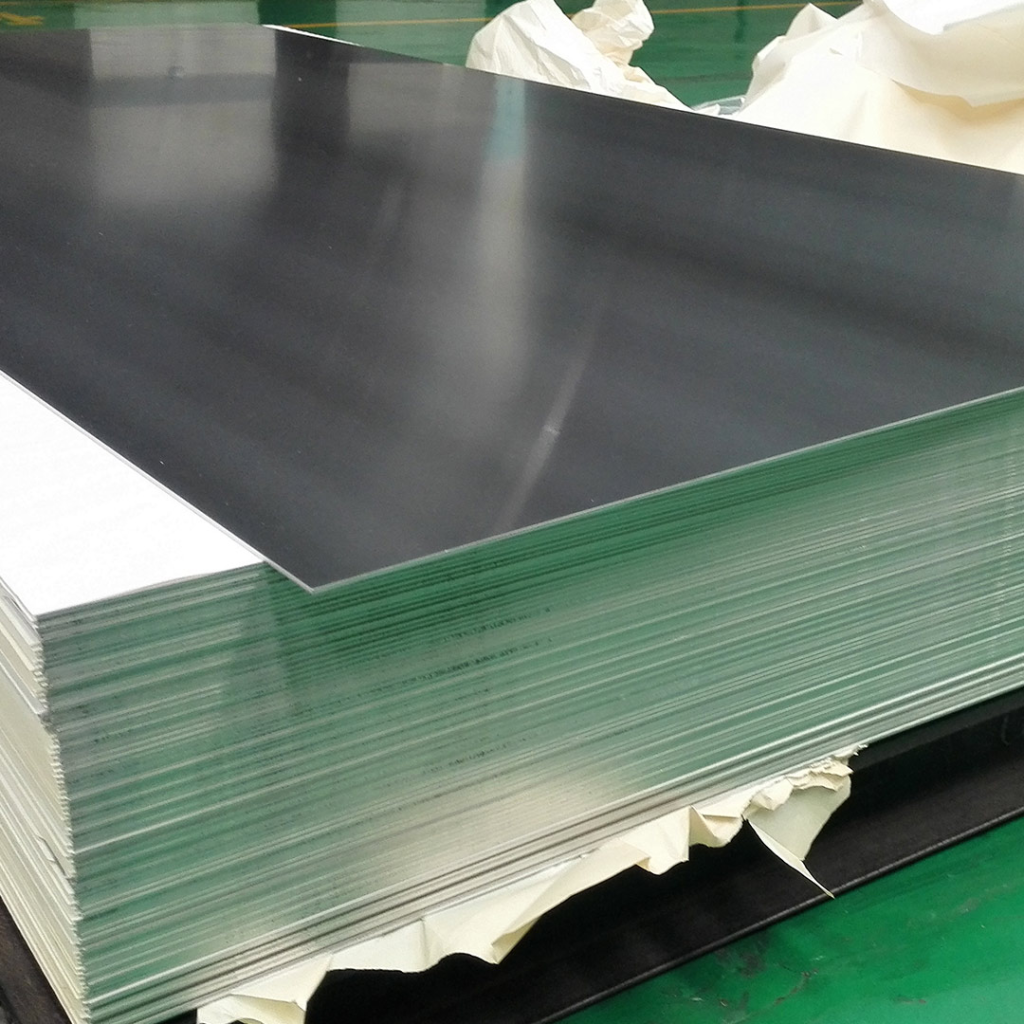

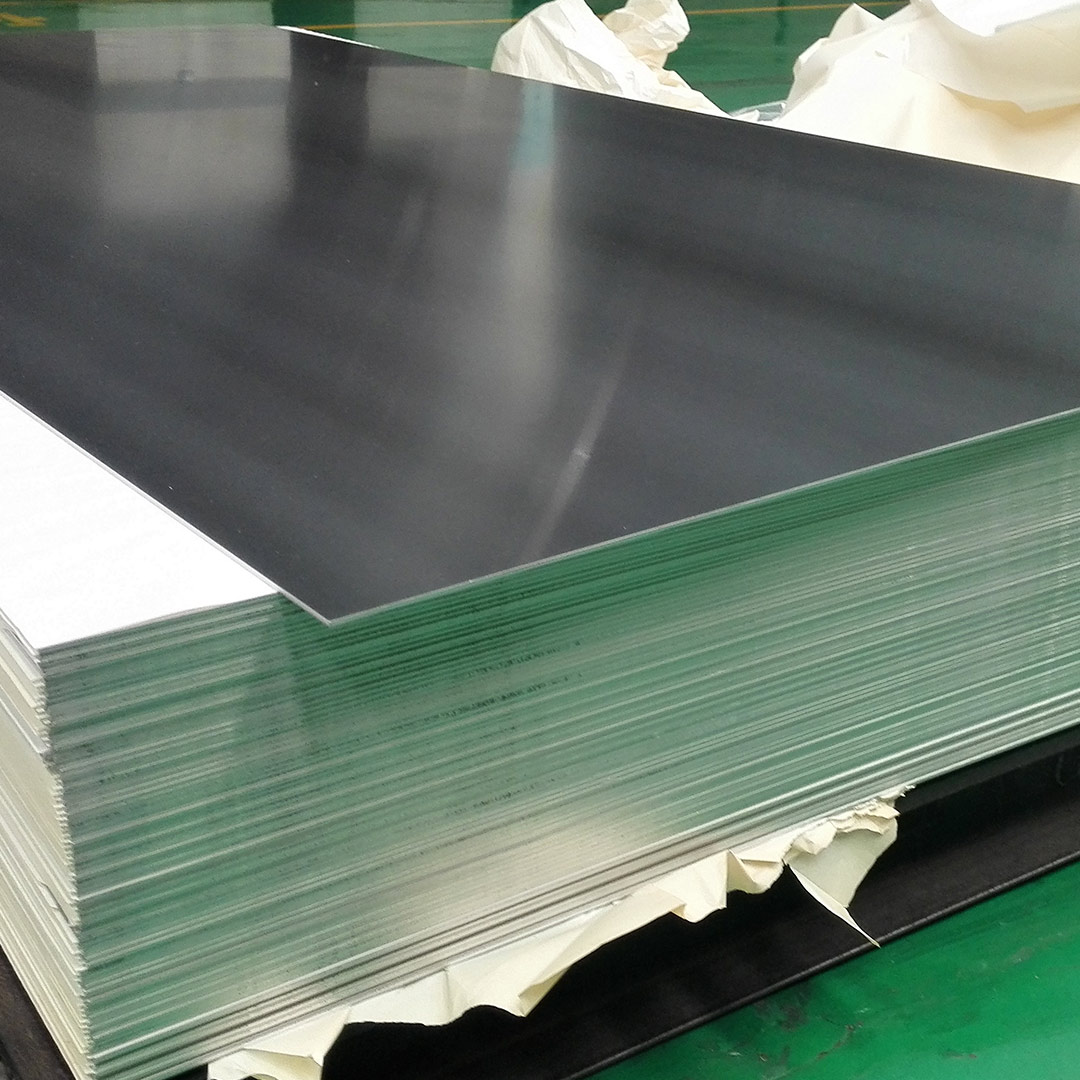

Aluminium Plain Sheet

- Material: Alloy aluminum

- Property: Anti-corrosion, heat resistant, fireproof

- Surface: Mill finish, no stains, without rough selvage,glitch-free

- Process: CC &DD

- Thickness: 0.2mm-300mm

- Width: 915mm-3000mm

- Length: Max 11000mm

- Standard: GBT3880-2012,AMS-QQA-250/12,AMS-4027,BS1470, ASTMB209, EN485 and JIS H4000

Product Description

Aluminium plain sheet refers to the rectangular plate made by rolling aluminum ingot, which is divided into the pure aluminium plate, alloy aluminium plate, thin aluminum sheet, medium thickness aluminium plate, and pattern aluminium plate. The building, curtain wall, ceiling, panels, transformers, food packaging, air conditioning, condenser, air filter, refrigerators, washing machines, solar energy, automobile manufacturing, ship manufacturing, machinery manufacturing, electric equipment such as cosmetic packaging, machinery manufacturing industry, can also be used in power plants, chemical anti-corrosion insulation in the petrochemical industry, etc.

Specification of Plain Aluminium Sheet

| Product Name | Aluminium plate/sheet |

| Material | Alloy aluminum |

| Property | Anti-corrosion, heat resistant, fireproof |

| Surface | Mill finish, no stains, without rough selvedge,glitch-free |

| Process | CC &DD |

| Thickness | 0.2mm-300mm |

| Width | 915mm-3000mm |

| Length | Max 11000mm |

| Standard | GBT3880-2012,AMS-QQA-250/12,AMS-4027,BS1470, ASTMB209, EN485 and JIS H4000 |

| Package | Export wooden pallets, craft paper, anti-blushing agent. |

| Application | Building,Boat,Truck,Tanker,Machine |

| Delivery Time | 20-30 days |

| Payment Term | 30% TT down payment, 70% TT against BL copy or 100% LC at sight |

| Alloy | Temper | Thickness | Width | Length | Usage |

| 1100/1050/1060/1070/1200 | HO H12 | Building | |||

| 3003/3004/3104/3005/3105 | H16 H18 | 0.2mm | 915mm | Boat | |

| 5005/5052/5082/5754/5182 | H24 H32 | | | | | Max | Truck |

| 6961/6082 | H36 T651 | 200mm | 3000mm | 11000mm | Tanker |

| 8011 | T4 T6 | Machine |

Advantages of Aluminium Plain Sheet

- The product complies with ROHS and REACH environmental protection standards;

- Strictly control and test the alloy, state and performance of the coils to ensure the accuracy and diversity of the aluminium plates provided;

- The introduction of advanced and efficient production equipment has improved the production efficiency of aluminum plates and the utilization rate of materials, effectively shortened the production cycle, and provided customers with real-time convenient services;

- The aluminum plate is classified in detail, and the accurate type can be selected according to the different uses and requirements of customers;

- Good control of the grain size and elongation of the plate in the early stage;

- The product packaging is firm, in line with domestic sales and international export standards.

Working Process of Aluminum Plain Sheet

This workshop produces aluminum circles through a calendaring process, with the material of international standards aluminium ingots.

Ingot & Master Alloy — Melting & Holding Furnace — DC caster — Slab — Milling — Preheating Furnace — Reversing Hot Rolling Mill — 3 Stand Tandem Hot Rolling Mill — Cold Rolling — Annealing Process — Tension Leveller — Slitting Blanking Press — thick plate