Aluminium Chequered Plate

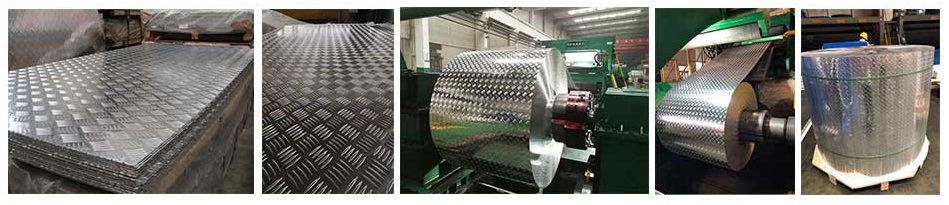

As a leading manufacturer of aluminum products, Lanren is committed to producing high-quality Aluminium Chequered Plates. Our Aluminium Chequered Plates are known for their outstanding anti-slip properties and robust durability, making them ideal for use in stairs, flooring, vehicle interiors, and more. With a strong emphasis on craftsmanship and rigorous quality control, Lanren delivers modern, visually appealing, and cost-effective aluminum solutions. Choosing Lanren means opting for reliability, innovation, and exceptional quality from a trusted industry leader.

Product Description

Aluminum chequered plate, also known as Aluminum Diamond Sheets, is a premium, contemporary material available in various types and is extensively used in furniture, including refrigerators, air conditioners, carriages, platforms, packaging pipes, screen frames, suspension beams, table legs, decorative strips, handles, wire grooves and covers, chair tubes, and more.

The primary functions of aluminum chequered plate are anti-skid protection and decoration. It is commonly employed in specialized areas like cold storage, ships, carriages, and stairs. Additionally, it finds widespread use in furniture, such as refrigerators, air conditioners, carriages, platforms, packaging pipes, screen frames, suspension beams, table legs, decorative strips, handles, wire grooves and covers, chair tubes, among other applications.

Specifications of Aluminium Chequered Plate

| Product Name | Aluminium chequered plate/sheet |

| Material | Alloy aluminium |

| Property | Anti-corrosion, heat resistant, fireproof |

| Surface | Mill finish, no stains, without rough selvedge, glitch-free |

| Process | CC &DD |

| Thickness | 1.0mm-6.0mm |

| Width | 915mm-1500mm |

| Length | Max 11000mm |

| Standard | GBT3880-2012,AMS-QQA-250/12,AMS-4027,BS1470, ASTMB209, EN485 and JIS H4000 |

| Package | 30% TT down payment, 70% TT against BL copy, or 100% LC at sight |

| Application | Building, Boat, Truck, Tanker, Machine |

| Delivery Time | 20-30 days |

| Payment Term | 30% TT down payment, 70% TT against BL copy or 100% LC at sight |

| Alloy | Temper | Thickness | Width | Length | Type | Surface | Usage |

| 1100/1050/1060 | HO H12 | Big 5 bar | Mill Finished | Truck,Bus,Car | |||

| H14 H16 | 1.0mm | 915mm | Max | Small 5 bar | & | Platform | |

| 3003/3105 | H18 H19 | | | | | 11000mm | Two bar | Bright | Suitcase |

| 5005/5052/5754 | H24 H32 | 1500mm | 1500mm | Diamond | Finished | Decoration | |

| 6061 | H36 T6 | Floor |

Features of Aluminium Chequered Plate

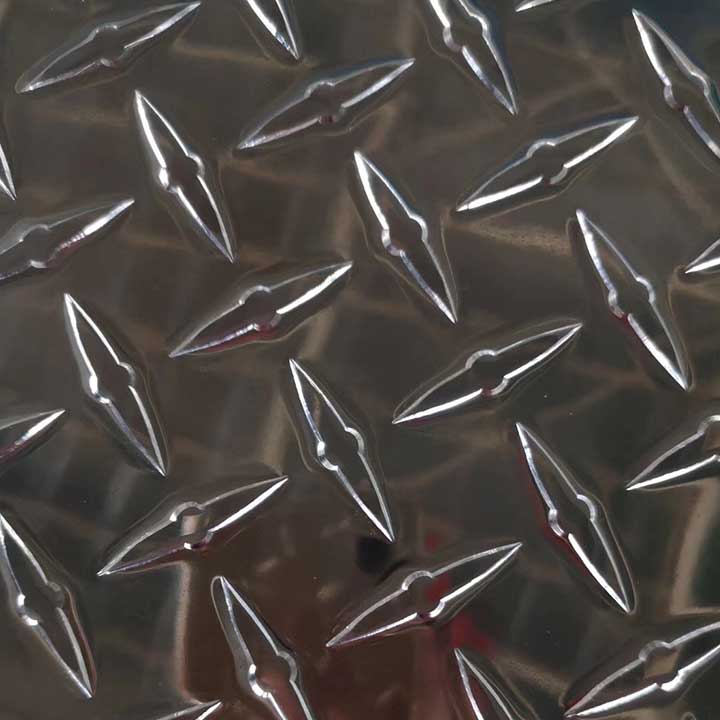

- Distinctive Non-Slip Texture: The unique chequered pattern on the surface provides excellent grip, making it highly effective for anti-slip applications.

- Exceptional Durability: Aluminium chequered plates offer superior corrosion resistance, hardness, and rust resistance, ensuring long-lasting performance even in harsh environments.

- Lightweight Advantage: Compared to other metals, aluminium is significantly lighter, making the chequered plate easier to handle, transport, and install without compromising on strength.

- High Strength and Load-Bearing Capacity: Despite its lightweight nature, aluminium chequered plates boast high hardness and can support substantial loads, making them ideal for demanding applications.

Advantages of Aluminium Chequered Plate

- Aluminium chequered plate specifications are available. In addition to regular sizes, plates with the thinnest 1.0mm and the thickest 6.0mm can be provided;

- The surface performance of the aluminium chequered plate is good, and there is no obvious scratches, oil stains, oxidation, black spots, etc.;

- When the thickness of the aluminum tread plate is greater than 1.0 mm, ensure that the edges of the finished product are neat and free of burrs;

- Good control of the grain size and elongation of the plate in the early stage;

- Strictly control and test the alloy, state and performance of the coils to ensure the accuracy and diversity of the aluminium chequered plates provided.

Applications

- Aluminum chequered plates are widely used as tread plates, flooring decks, and anti-slip surfaces in various settings including industrial environments, transportation, and residential areas. They are ideal for providing safe and secure walking surfaces on stairs, walkways, and other high-traffic areas.

- These plates serve as effective building materials and are popular for decorative cladding. They can be applied to walls, ceilings, and facades, enhancing both aesthetics and durability.

- In vehicles and machines, aluminum chequered plates are used for anti-slip flooring, paneling, and protective surfaces. They offer a combination of strength, functionality, and visual appeal.

- The chequered plates come in various designs, including one-bar, two-bar, three-bar, five-bar, diamond, embossed, and decorative patterns. These can be tailored to meet specific client requirements.

- The plates are primarily made from a blend of aluminum, magnesium, and silicon, ensuring both quality and performance.

- Available in mill finish and embossed surface treatments, these plates offer versatility in both appearance and functionality.

lanren Aluminum chequered plates blend quality, functionality, and aesthetic appeal, making them a versatile choice for numerous applications in both industrial and decorative contexts.

Why Choose Lanren Aluminium Chequered Plate

- Superior Durability: Lanren Aluminium Chequered Plates are crafted from high-grade aluminium, offering exceptional strength and resistance to wear, corrosion, and impact. This ensures long-lasting performance even in demanding environments.

- Versatile Applications: Our chequered plates are designed for a wide range of uses, including flooring, stair treads, and decorative elements. They provide excellent anti-slip properties and aesthetic appeal, making them a versatile choice for various projects.

- Lightweight Yet Strong: Lanren Aluminium Chequered Plates combine a lightweight design with robust strength, facilitating easy handling and installation without sacrificing structural integrity.

- Customization Options: We offer tailored solutions to meet specific project requirements, including custom thicknesses, patterns, and finishes, ensuring the perfect fit for your unique needs.