About Aluminium Tempering Name

Aluminum is known for its multi-functionality. The flexibility and adaptability of the mechanical properties of aluminum make aluminum a widely used metal, while superior corrosion resistance and excellent thermal conductivity are very useful in many applications. The mechanical properties of aluminum can be changed by a variety of ways, such as adding alloy elements or processing, but one of the most popular methods of changing the mechanical properties of certain grade aluminium is by tempering. Since tempering will have such a significant impact on aluminum alloys, it is extremely important to understand the backulum code and its meaning of aluminum, so as not to misunderstand the rupture and destruction.

What is aluminum tempering name?

The aluminum returns are a series of letters and numbers, which are used to indicate which type of tempering process has undergone the aluminum alloy. The temper mark has a broken number and is placed after an aluminum alloy tag (for example, 6061-T6). Understanding the meaning of aluminium tempering names is essential for choosing the right material. It is important that the aluminium alloy can be identical to another aluminium alloy on the chemical composition, but if the temper name of the two is different, the mechanical properties of the two alloys may be large.

What is the name of the aluminum tempering?

The aluminum tempering identification has four main types. These types are represented by the letters in front of the numbers. Four letters designated as:

T: heat treatment

H: strain hardening

O: annealing

F: artificial

The almomment of aluminum tempering symbol is a number. The digitally accurately specifies the way of execution of the tempering method. For example, T5 and T6 are heat-treated, but T5 represents the aluminum alloy has been cooled and artificially processed from a high temperature molding process, while T6 performs a solution heat treatment, and then performs artificial aging treatment. The quantity difference between the aluminum tuning and mixing name can inform the aluminum alloy purchaser’s information about fineness, these subtle differences may have a significant impact on the mechanical properties of the alloy.

Although a variety of digital variants can be used, “T” digital variants may be most common and the most important understanding. Here are some instructions for “T” code variants:

T1: Natural aging after cooling from the high temperature during the formation process

T2: Cooling, cold processing from the high temperature molding process, then natural aging

T3: Solution heat treatment, cold processing, then natural aging

T4: Natural aging after solid solution heat treatment

T5: Cooling from high temperature during forming process

T6: artificial aging after cooling from solid solution heat treatment

T7: Excessive aging after solid solution heat treatment

T8: solid solution heat treatment, cold processing, then manual aging

T9: solid solution heat treatment, labor time, then cold processing

T10: Cooling, cold processing from the high-temperature molding process, then manual aging

For alphabet alpha numbers (eg, “O”, “H”, “H”, “H”, “H”, “f”), it is best to obtain the technical data table of aluminum alloy to determine the exact letter meaning.

Lanren Aluminium

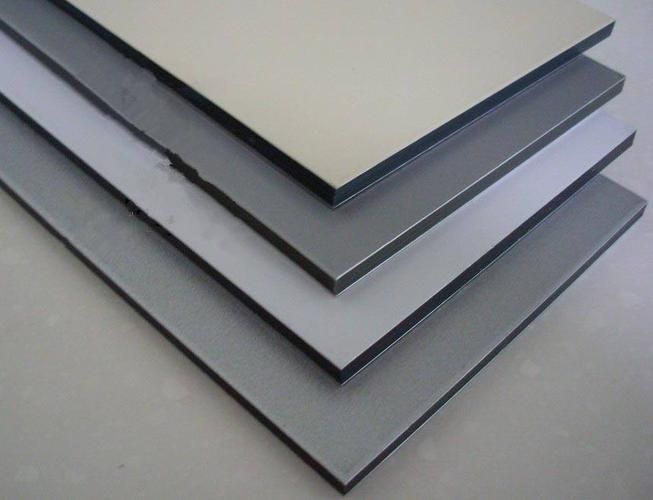

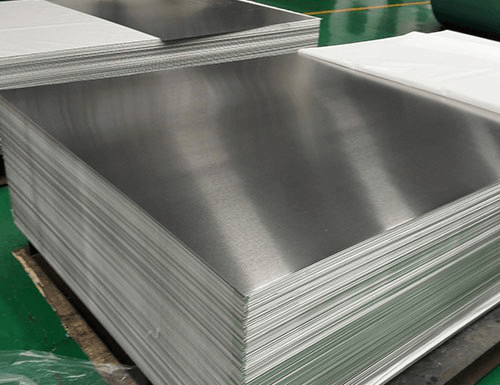

Chongqing Lanren Aluminium Co., Ltd was established in 2008, which is a professional manufacturer of aluminium material and aluminium cookware, and we have the whole line to produce aluminium coil, aluminium plate, aluminium circles and aluminium cookware. We can also offer OEM services to complete our clients customized orders, and welcome to visit our company and establish good business relationship.