Features of 5052 Aluminum Circle

- 5052 aluminum circles have moderate tensile strength and yield strength, suitable for a variety of applications.

- Magnesium makes 5052 aluminum circles have excellent corrosion resistance, especially in marine and humid environments.

- 5052 aluminum circles are easy to weld, and the strength and corrosion resistance are not affected after welding.

- Surface treatments such as anodizing and spraying can be easily performed to improve aesthetics and durability.

Advantages of 5052 Aluminum Circle

- Wide range of applications: suitable for automotive parts, shipbuilding, architectural decoration, kitchenware and other fields.

- Cost-effectiveness: Compared with others, 5052 aluminum circles are more economical in cost while ensuring performance.

- Environmentally friendly: recyclable and reusable, in line with environmental protection requirements.

Specification of 5052 Aluminum Circle

| Product | 5052 Aluminium Circle |

| Alloy | 5052 |

| Temper | O、H12、H14、H16、H18、H24、H32、H36 |

| Thickness | 0.4mm-10mm |

| Diameter | 60mm-1200mm |

| Surface | The surface is bright and smooth, without defects such as white rust, oil spots, edge damage, etc. |

| Delivery Time | Within 30-45 days after receiving deposit |

| Packaging | Export standard packaging: wooden pallet + cardboard + steel bar fixed |

| Material | Using high-tech machinery and high-quality aluminum coils. |

| Color | Silver |

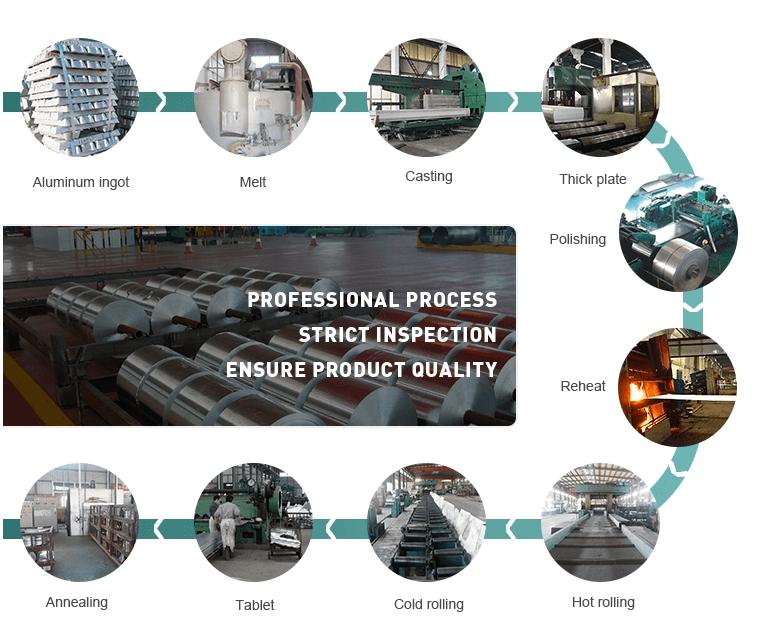

Product Process of 5052 Aluminum Circle

Aluminum ingot melting → Casting → Plate polishing → Annealing (first time) → Cold rolling → Hot rolling and reheating → Annealing (second time) → Cold rolling (second time) → Final annealing → Quality control and inspection

QC(Quality Control)

- Production process monitoring records: Including key parameters such as melting temperature, refining time, rolling pressure, etc., to ensure that the production process is stable and controllable.

- Finished product inspection report: Covers comprehensive testing of dimensions, surface quality, mechanical properties, hygiene indicators, etc. to ensure that product quality meets relevant standards.

- Defective product handling records: Detailed record of the handling process and results of defective products to ensure that defective products are effectively controlled and prevented from entering the market.

- Quality improvement plan: Based on customer feedback and test results, formulate and implement quality improvement plans to continuously improve product quality and customer satisfaction.

Why Choose Us?

Choose Chongqing Lanren Aluminum, because we are the industry-leading aluminum circle and aluminum products expert, integrating R&D, production and sales, with strong technical strength and rich production experience. We focus on quality and innovation, and our products are diverse and of excellent quality. The perfect after-sales service system ensures that customers are worry-free. Trust Lanren Aluminum and create a brilliant future together!

Packing&Delivery

1. Standard seaworthy export packaging. Coils and sheets use wooden pallets with plastic protection;

2. Packaging can face the sky or the wall according to customer requirements;

3. 16-20 tons can be loaded into 20FCL, and the freight is much cheaper than 40FCL;

4. Delivery time: 15-35 days after receiving L/C or 30% deposit.

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a factory established in 2008, located in Nanping Industrial Park, Nanchuan District, Chongqing City, and are the leading aluminum cookware manufacturer in western China.

Q2: Can you send samples?

A: Yes, we can provide free samples, but freight is required.

Q3: What product information do I need to provide?

A: You need to provide the brand, width, thickness, coating and tonnage you need to purchase.

Q4: How long does your delivery time take?

A: Generally, our delivery time is 30-45 days. If the demand is extremely large or there are special circumstances, it may be delayed.

Q5: Can I visit your factory?

A: Of course, we welcome customers from all over the world to visit our factory. However, some factories are not open to the public.