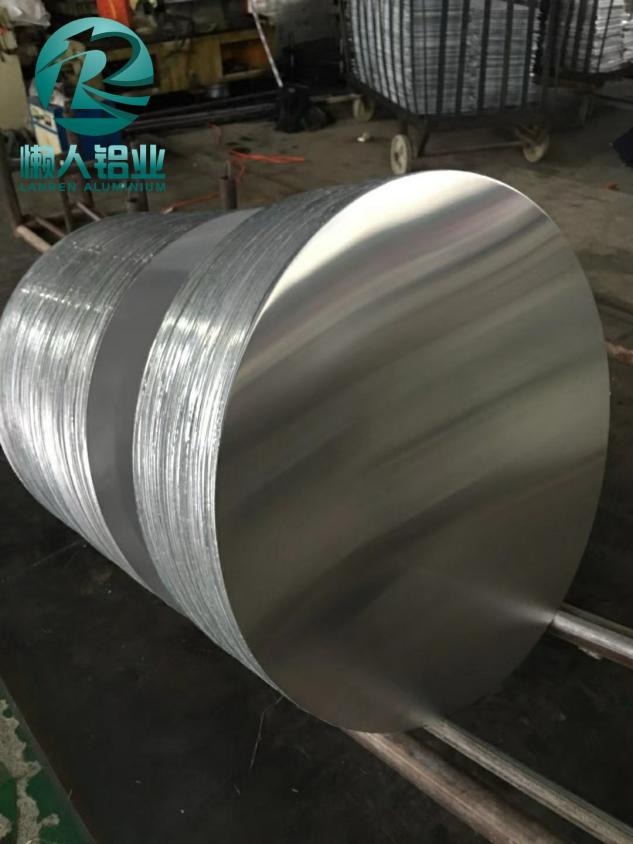

3105 Aluminum Circle

- Thickness and Diameter: Customized

- Certification: ISO9001/SGS/FDA

- Grade: 1000 series:1050 1060 1100; 3000 series:3003 3105

- Usage: Cookwares like kitchen utensils, stock pot, frying pan, rice cookers, lighting lamp, traffic sign, etc.

- Condition: Cold Rolling / Hot Rolling

Features of 3105 Aluminum Circle

- 3105 Aluminum Round Sheet belongs to Al-Mg-Si system alloy, which has high alloy strength and corrosion resistance. Its grain size is fine, with good mechanical properties and processing performance.

- Physical properties: 3105 aluminum round sheet has good rust resistance and electrical conductivity. In the annealed state, its plasticity is high, cold hardening plasticity is low, but good corrosion resistance and weldability.

- Processing performance: 3105 aluminum round sheet is easy to process, can be cut, drilled, bent and other operations, suitable for mass production. Its surface treatment is various, such as oxidation, spraying, etc., which can be customized according to the demand.

- Application Areas: 3105 aluminum round sheet is widely used in various industrial and architectural fields, such as automobile manufacturing, architectural curtain wall, solar water heater and so on. Due to its light weight, high strength and corrosion resistance, it is also commonly used in the manufacture of airplane parts, daily life products and doors and windows for construction.

The Advantage Of 3105 Aluminum Circle

- Corrosion resistance: 3105 aluminum wafer has good corrosion resistance, especially its manganese element, can effectively resist oxidation and corrosion, especially suitable for use in humid environment and bad weather conditions, so as to extend the service life.

- Processing performance: 3105 aluminum wafer has good processing performance, can be cut, drilling, bending and other processing, convenient and fast, suitable for a variety of processing technology, such as stamping, bending and so on.

- Surface treatment performance: 3105 aluminum wafer can be surface treated by spraying, anodizing and other methods to increase its beauty and use function, suitable for building exterior walls and interior decoration.

- Lightweight and high strength: 3105 aluminum cirlces are light in weight and high in strength, which can reduce the overall weight of the structure while ensuring good strength and toughness, so they are widely used in buildings and vehicles.

- Extensive application areas: 3105 aluminum wafers are widely used in construction, automobile manufacturing, solar water heaters and other fields, and are suitable for use in various complex environments.

Specification of 3105 Aluminum Circle

- Aluminium Circle Specification

| Temper | O, H12, H14,H16,H18,H22,H24,H26,H32, etc. |

| Alloy | 1050,1060,1070, 1100,1200, 3003, 3004,5052, 8011, etc. |

| Thickness | 0.4mm-10mm |

| Diameter | 60mm-1200mm |

| Type | CC&DC |

| Certification | ISO9001/SGS/FDA |

| Material | Using high-tech machinery utilizing premium grade aluminium Coil. |

- Detailed Product Description

| Alloy | 1050,1060,1070, 1100,1200, 3003, 3004,5052, 8011, etc. |

| Temper | O, H12, H14,H16,H18,H22,H24,H26,H32, etc. |

| Thickness | 0.4mm-10mm |

| Diamters | 60mm-1200mm |

| Application | Kitchen utensils, stock pot, frying pan, rice cookers, lighting lamp, traffic sign, etc. |

| MOQ | 500kgs per size |

| Certification | ISO9001/SGS/FDA |

(3)Chemical Composition (%)

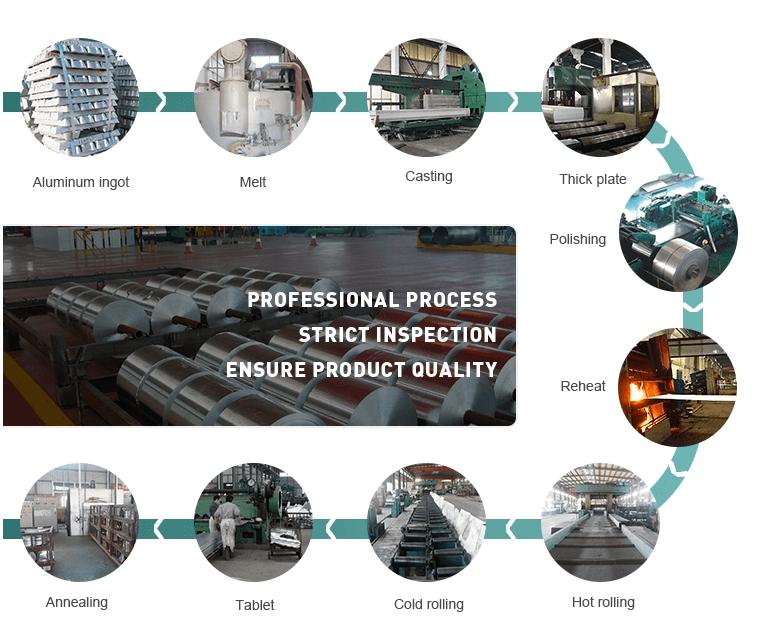

Product Process of 3105 Aluminum Circle

We have CC and DC materials, this is the difference between DC and CC material,

- Hot rolling process( Direct Cast rolling-DC): Aluminium ingot → Melting casting → Slag removal → Milling surface → Heating → Hot rolling → Cold rolling → Finishing rolling → Cut into circles

- Casting and rolling process(Continuous Casting Rolling-CC): Melting casting → Crystal cooling forming → Cold rolling → Finishing rolling → Cut into circles

QC(Quality Control)

- Products comply with ROHS, REACH environmental standards.

- We have many customers all over the world, have our own R&D and production team, have quality testing certificates, ISO9001, SGS and other quality testing certificates, and our products are in line with the national standards.

Why Choose Us?

- Sample service: We provide free samples for testing, and the shipping cost is paid by customers;

- Customized service: Customized samples are welcome. Professional design team and excellent mold engineers to meet your different needs. We will make samples for you within 7-15 working days after receiving your drawings and mold cost;

- Processing service: bending, uncoiling, welding, punching, cutting;

- After-sales service: we have professional after-sales service staff to receive your suggestions 24 hours;

- We welcome your agent or third-party organization for inspection or factory inspection.

Packing&Delivery

- (1) Wooden case, carton, pallet, or customized etc.

- (2) Wooden pallet packing (and send pictures of packing method).

- (3) Standard shipping package, wooden case or pallet.

- (4) Wooden pallet for whole container, wooden crate for consolidation.

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a factory established in 2008, located in Nanping Industrial Park, Nanchuan District, Chongqing, and we are a leading manufacturer of aluminum cookware in western China .

Q2: Can you send samples?

A: Yes, we can provide free samples, but we need to charge shipping fee.

Q3: What product information do I need to provide?

A: You need to provide the grade, width, thickness, coating and tonnage you need to purchase.

Q4: How long does your delivery time take?

A: Generally our delivery time is 30-45 days, if the demand is very large or there are special circumstances, it may be delayed.

Q5: Can I visit your factory?

A: Of course, we welcome customers from all over the world to visit our factory. However, some factories are not open to the public.

Q6: What are your working hours?

A: Generally, our online service time is Beijing time: 8:00 a.m. – 22:00 p.m. After 22:00 p.m., we will reply to your inquiry on the next working day.