Features of 3004 Aluminum Circle

- Composition and strength: 3004 aluminum rounds belong to aluminum-manganese alloy, which is higher than 3003 series, but not as strong (slightly higher than industrial pure aluminum). As it can not be strengthened by heat treatment, usually through cold working methods to improve its mechanical properties.

- Formability and weldability: 3004 aluminum round sheet has high plasticity in the annealed state, and still maintains good plasticity when semi-cold work hardening, but the plasticity will be reduced when cold work hardening. It has good weldability and excellent corrosion resistance, especially strong resistance to chloride corrosion, and is suitable for work in humid and corrosive environments.

- Application areas: 3004 aluminum round sheet is widely used in areas where high strength and good formability are required. For example, it is suitable for low load parts working in liquid or gaseous media, such as mailboxes, gasoline or lubricating oil conduits, and small load parts made by deep drawing. In addition, it is used in kitchenware, food and chemical product handling and storage units, and tanks for the transportation of liquid products.

- Price and market applications: 3004 aluminum rounds are more widely used in the market due to their lower price than 5-series products.

Advantages of 3004 Aluminum Circle

- Strong corrosion resistance: 3004 aluminum round sheet has good corrosion resistance and can effectively resist corrosive media in the atmosphere, such as rain, salt spray, etc.

- Light weight and high strength: 3004 aluminum round sheet has low density and light weight, but the strength is not inferior, which can reduce the self-weight of the building, and is conducive to the optimal design of the structure and energy saving and emission reduction.

- Easy processing and molding: it has good ductility and plasticity, and is easy to be processed into various complex shapes by shearing, bending, stamping and other processes.

- Good decorative properties: the surface can be sprayed, fluorocarbon spraying and other treatment methods, presenting rich colors and texture effects to enhance the overall aesthetics of the building.

Specification of 3004 Aluminum Circle

- Aluminium Circle Specification

| Temper | O, H12, H14,H16,H18,H22,H24,H26,H32, etc. |

| Alloy | 3004 |

| Thickness | 0.4mm-10mm |

| Diameter | 60mm-1200mm |

| Type | CC&DC |

| Certification | ISO9001/SGS/FDA |

| Material | Using high-tech machinery utilizing premium grade aluminium Coil. |

- Detailed Product Description

| Application | Kitchen utensils, stock pot, frying pan, rice cookers, lighting lamp, traffic sign, etc. |

| MOQ | 500kgs per size |

- Chemical Composition (%)

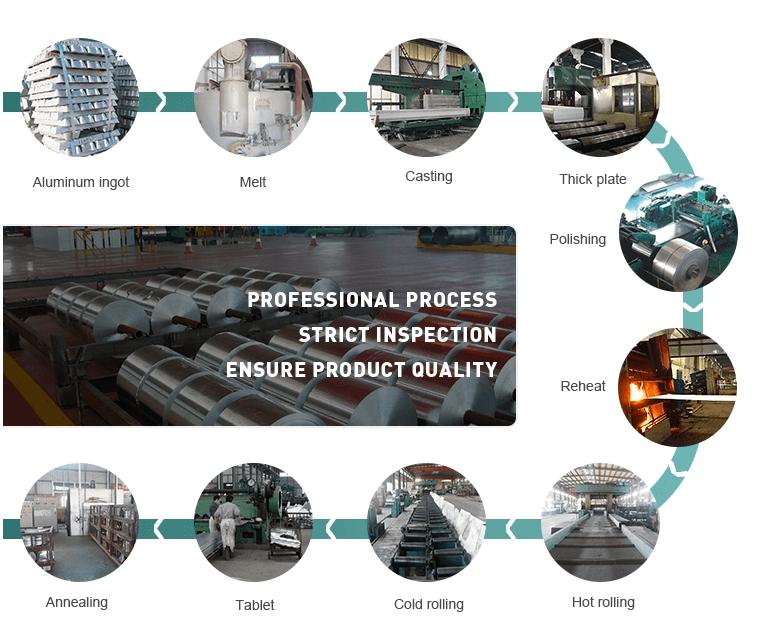

Product Process of 3004 Aluminum Circle

We have CC and DC materials, this is the difference between DC and CC material,

- Hot rolling process( Direct Cast rolling-DC): Aluminium ingot → Melting casting → Slag removal → Milling surface → Heating → Hot rolling → Cold rolling → Finishing rolling → Cut into Discs

- Casting and rolling process(Continuous Casting Rolling-CC): Melting casting → Crystal cooling forming → Cold rolling → Finishing rolling → Cut into Discs

QC(Quality Control)

- Products comply with ROHS, REACH environmental standards.

- We have many customers all over the world, have our own R&D and production team, have quality testing certificates, ISO9001, SGS and other quality testing certificates, and our products are in line with the national standards.

Why Choose Us?(About Company)

- Sample service: We provide free samples for testing, and the shipping cost is paid by customers;

- Customized service: Customized samples are welcome. Professional design team and excellent mold engineers to meet your different needs. We will make samples for you within 7-15 working days after receiving your drawings and mold cost;

- Processing service: bending, uncoiling, welding, punching, cutting;

- After-sales service: we have professional after-sales service staff to receive your suggestions 24 hours;

- We welcome your agent or third-party organization for inspection or factory inspection.

Packing&Delivery

- (1) Wooden case, carton, pallet, or customized etc.

- (2) Wooden pallet packing (and send pictures of packing method).

- (3) Standard shipping package, wooden case or pallet.

- (4) Wooden pallet for whole container, wooden crate for consolidation.

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a factory established in 2008, located in Nanping Industrial Park, Nanchuan District, Chongqing, and we are a leading manufacturer of aluminum cookware in western China .

Q2: Can you send samples?

A: Yes, we can provide free samples, but we need to charge shipping fee.

Q3: What product information do I need to provide?

A: You need to provide the grade, width, thickness, coating and tonnage you need to purchase.

Q4: How long does your delivery time take?

A: Generally our delivery time is 30-45 days, if the demand is very large or there are special circumstances, it may be delayed.

Q5: Can I visit your factory?

A: Of course, we welcome customers from all over the world to visit our factory. However, some factories are not open to the public.

Q6: What are your working hours?

A: Generally, our online service time is Beijing time: 8:00 a.m. – 22:00 p.m. After 22:00 p.m., we will reply to your inquiry on the next working day.