ABOUT US

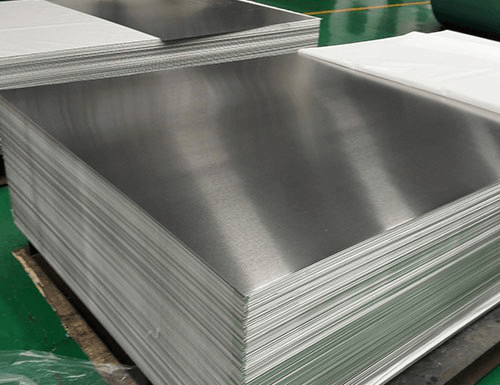

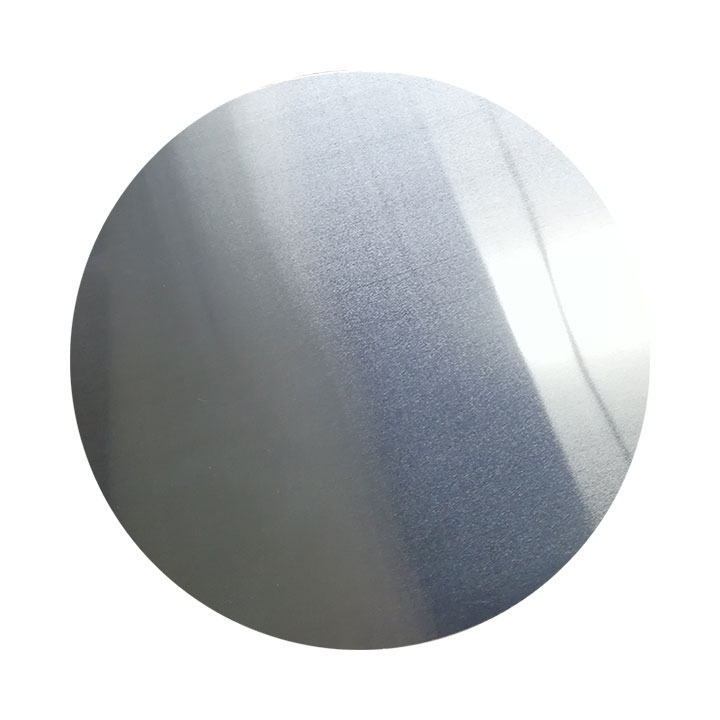

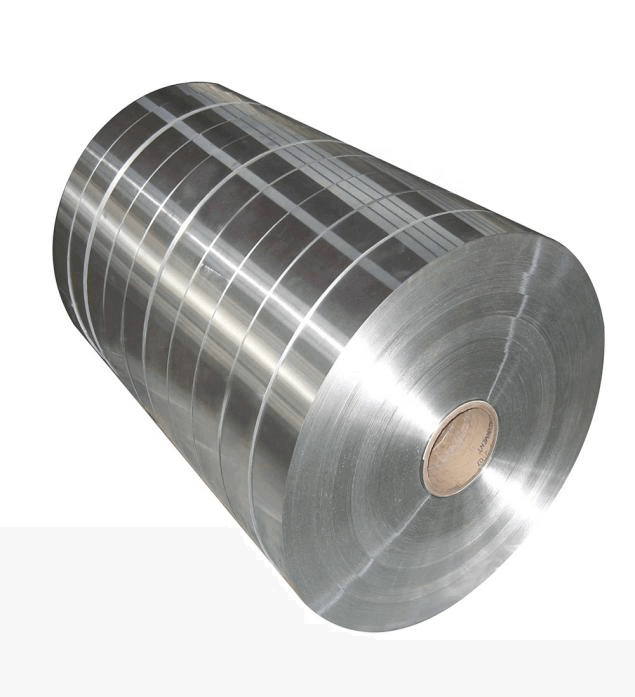

Chongqing Lanren Aluminium Co.,Ltd was established in 2008,which is a professional manufacturer of aluminium cookware and non-stick cookware, and we have the whole line to produce aluminium circles to make aluminium cookware. Our company occupies an area of nearly 50,000 square meters and have more than 300 employees,and Lanren has become into a comprehensive aluminium fabrication enterprise for its production scale,advanced equipment,full-ranged products varieties in China.

NEWS

Aluminum Coil V.S Ceramic Cookware

How Aluminum Foil Lunch Box Save Our Planet?

What Should You Pay Attention at When Purchasing Aluminum?

Why is aluminum more efficient than steel?

SERVICE

01 – Reply within 8 hours

Lanren Aluminium

02 – Free samples provided

Lanren Aluminium

03 – On-site production following-up

Lanren Aluminium

04 – Total quality management

Lanren Aluminium

05 – Well-organized Logistic facility

Lanren Aluminium

06 – Max. customer satisfaction

Lanren Aluminium